+86-731-89578196

+86-731-89578196

[email protected]

[email protected]

- Home

- Our Company

-

Products

Sputtering Targets

- Industries

- Blog

- FAQ

- Contact Us

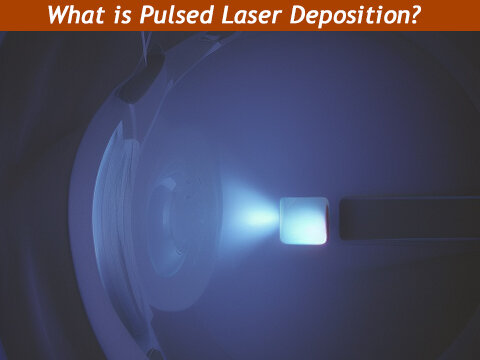

What is Pulsed Laser Deposition: An In-Depth Exploration

In the world of material science, innovation is crucial. New techniques and technologies continually revolutionize our understanding and capabilities in this field. One technique generating excitement is Pulsed Laser Deposition (PLD). But what is PLD and why is it special? Join us on a journey to explore this fascinating technique and uncover its secrets.

Understanding Pulsed Laser Deposition

Pulsed Laser Deposition (PLD) is a technique used to create thin films of various materials. It works by using a high-power pulsed laser beam to strike a target material, causing the formation of a plasma plume. This plasma plume then deposits onto a substrate, resulting in the formation of thin films. PLD is a versatile process that can be used to create thin films composed of a wide variety of materials.

Advantages of Pulsed Laser Deposition

1. Improved Film Quality

Pulsed Laser Deposition (PLD) offers several advantages in the deposition of thin films. One of the key benefits is the ability to achieve high film quality. The controlled laser pulse allows for precise control over the deposition process, resulting in films with excellent structural and surface properties.

2. Versatility in Material Selection

Another advantage of PLD is its versatility in material selection. This technique can be used to deposit a wide range of materials, including metals, oxides, nitrides, and more. It can be used for both conductive films and insulating layers, which means it can help achieve different properties.

3. Control over Film Thickness

PLD also offers precise control over film thickness. By adjusting the laser pulse energy and duration, you can control the amount of material deposited per pulse, allowing for accurate control of the film thickness. This level of control is crucial for applications where precise film thickness is required, such as in the manufacturing of electronic devices.

4. Scalability and Reproducibility

Pulsed Laser Deposition is a scalable technique that can be easily adapted for large-scale production. The process parameters can be optimized to ensure reproducibility and consistency in film quality across different batches. This scalability and reproducibility make PLD a reliable method for industrial applications.

Conclusion

Pulsed Laser Deposition (PLD) is a technique used to deposit thin films with many advantages. It improves film quality, allows for a wide range of materials, and provides precise control over film thickness. PLD is valuable for thin film deposition because it is easy to understand and read. It is a great choice for researchers and engineers due to its simplicity and clarity.

Disadvantages of Pulsed Laser Deposition

1. Complex Equipment Setup

PLD needs special equipment and settings that can be complicated and take a lot of time to set up. It requires experts to make sure everything works well.

2. Limited Material Compatibility

Not all materials can be used with PLD. Some materials might not stick well or get damaged. This means there are only certain things you can do with PLD.

3. High Energy Consumption

PLD typically requires high-energy laser pulses, leading to increased energy consumption. This can cost a lot of money and make it harder to use PLD for big projects.

4. Lack of Uniformity

It's not easy to make sure the deposition is even with PLD. The laser beam, the target getting worn out, and other things can make the film thickness and composition uneven. This can make the films not work as well or be reliable.

5. Substrate Temperature Sensitivity

PLD often requires elevated substrate temperatures during the deposition process. This temperature sensitivity can limit the choice of substrates and pose challenges for heat-sensitive materials. It can also make the films weak and less structurally sound.

While PLD has its benefits, it's important to know about these disadvantages when deciding if it's right for a specific application. By understanding these limitations, scientists and engineers can make smart choices and try other ways of depositing materials if needed.

The Multifaceted Applications of Pulsed Laser Deposition (PLD)

Pulsed Laser Deposition (PLD) is used in many different areas. Let's explore some of its applications:

Medical Applications:

-

PLD helps make medical implants work better in our bodies.

-

It also helps with tissue engineering and organ transplantation.

Thin Film Technology:

-

PLD is used to make thin films with precise control over thickness and composition.

-

It's used in electronics, optics, and energy storage.

Nanotechnology:

-

PLD is important for making tiny materials like nanoparticles.

-

It's used in electronics, photonics, and catalysis.

Energy and Environment:

-

PLD is used to make materials for energy conversion and storage, like solar cells and batteries.

-

It helps with environmental research too.

Pulsed Laser Deposition (PLD) is a powerful technique with diverse applications across various fields. Its flexibility and precision make it a valuable tool for researchers and engineers, driving advancements in technology, healthcare, energy, and beyond.

PLD VS Other Deposition Techniques

When it comes to depositing materials onto a surface, there are different methods to choose from. Let's take a look at three common techniques and how they compare to Pulsed Laser Deposition (PLD).

Thermal Evaporation

Thermal evaporation technique involves heating a material until it turns into a vapor and then letting it settle on a surface. It's simple and cost-effective, but it may not stick well to the surface and it's hard to control how thick or what it's made of.

Sputtering

Sputtering is another popular deposition technique that relies on bombarding a target material with high-energy ions to eject atoms or molecules that then deposit onto a substrate. Sputtering offers excellent film uniformity and control over film composition. However, it requires complex equipment and takes time.

Chemical Vapor Deposition (CVD)

This method creates a solid film by reacting gases together on a surface. CVD offers precise control over thickness and composition, but it can be expensive and requires special equipment and high temperatures.

PLD - A Unique Deposition Technique

Pulsed Laser Deposition (PLD) stands apart from other deposition techniques due to its unique advantages. PLD offers precise control over film composition, high film quality, and excellent adhesion. It allows for the deposition of a wide range of materials, including complex compounds and multi-layer structures. PLD is a versatile technique that is easy to implement, making it highly suitable for both research and industrial applications.

By understanding how PLD compares to other deposition techniques, researchers and engineers can choose the most appropriate method for their specific needs and achieve optimal results.

Factors that Affect PLD Deposition Rate

We're going to talk about the things that affect how quickly we can make thin films using Pulsed Laser Deposition (PLD). Understanding these factors is super important if we want to make really good thin films. Let's get started!

Laser Energy

The energy of the laser we use in PLD is a big deal. When we use higher laser energy, it can make the material we're working with break down faster, which means we can make thin films faster too. But we have to be careful because if the laser energy is too high, it can also damage the surface we're working on.

Target-Substrate Distance

The distance between the target (the material we're using) and the surface we're putting the thin film on is also really important. If the distance is shorter, we can make thin films faster because the material gets transferred more efficiently. But we need to make sure the distance is just right to avoid any problems.

Target Material and Properties

The target material we choose to work with and its properties can have a big impact on how fast we can make thin films. Different materials have different properties, like how easily they break down and how much of the material gets transferred. Other things like how pure the material is and what it's made of can also affect how fast we can make the thin films.

Substrate Temperature

The temperature of the surface we're working on also matters. If the temperature is higher, the thin film will grow faster because the molecules move around more easily. But we have to be careful because the temperature has to be just right for the material we're using and the quality of the thin film we want.

Conclusion

Controlling the deposition rate in PLD is crucial for achieving desired film properties. By understanding and optimizing the factors discussed above, researchers and engineers can enhance the efficiency and effectiveness of their PLD processes.

The Amazing Impact of PLD on Material Science

Pulsed Laser Deposition (PLD) has had a huge impact on material science. It has helped create thin films for microchips and semiconductors in the electronics industry, making them work better and faster.

Simply put, PLD is more than just a new tool—it's a game-changer that has revolutionized material science. With its incredible abilities and wide range of uses, PLD continues to drive innovation and push the boundaries of what is possible in the future.