Thermal Filaments

|

|

|

Thermal evaporation is a coating method used as part of the Physical Vapor Deposition process (PVD). The evaporation coils have a very high melting point which can make any metal to be boiled. There is no contamination of the substrates beacuse the high corrosion resistance and outstanding material purity of thermal filaments. AEM provides thermal filaments in a variety of shapes and numbers of wires.

To get the quotation for crucible or related information, you may click the “inquiry” button. Then fill in the inquiry form or reach us via email at [email protected], our sales department will reply to you as soon as possible.

Thermal Filaments Specifications

| Materials | Tungsten Filaments | Molybdenum Filaments |

| Symbol | W | Mo |

| Purity | 99.95% | 99.95% |

| Theoretical Density (g/cc) | 19.25 | 10.2 |

| Melting Point (°C) | 3,410 | 2617 |

| Thermal Conductivity | 174 W/m.K | 139 W/m.K |

Thermal Filaments Dimensions

| Type | Number of Strands | Coils | Length (mm) |

Length of Coils (mm) |

ID of Coils (mm) |

Diameter of Wires (mm) |

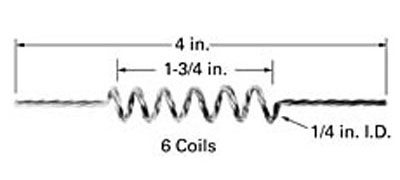

| TFC-1 | 1-strand or 3-strand | 6 coils | 101.6 mm | 44.45 mm | 6.35 mm | 0.762 mm or 1.905 mm |

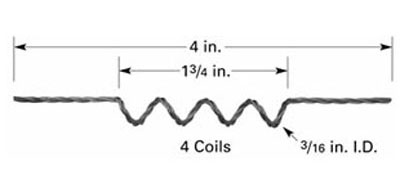

| TFC-2 | 1-strand or 3-strand | 4 coils | 101.6 mm | 44.45 mm | 4.76 mm | 0.762 mm or 1.905 mm |

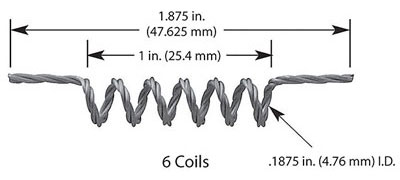

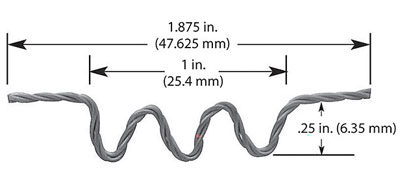

| TFC-3 | 1-strand or 3-strand | 6 coils | 47.625 mm | 25.4 mm (1") | 4.76 mm | 0.762 mm or 1.905 mm |

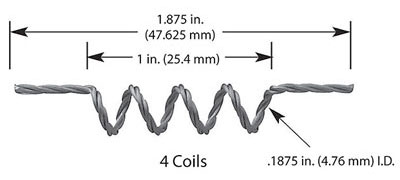

| TFC-4 | 1-strand or 3-strand | 4 coils | 47.625 mm | 25.4 mm (1") | 4.76 mm | 0.762 mm or 1.905 mm |

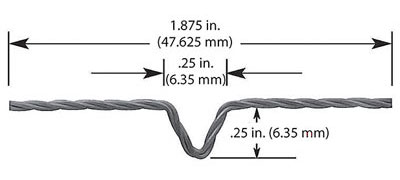

| TFV-5 | 1-strand or 3-strand | - | 47.625 mm | 6.35 mm | - | 0.762 mm or 1.905 mm |

| TFV-6 | 1-strand or 3-strand | - | 47.625 mm | 25.4 mm | - | 0.762 mm or 1.905 mm |

| The customized size can be porvided accroding to customer's drawings. | ||||||

Drawings of Thermal Filaments

|

|

|

||

| TFC-1 | TFC-2 | TFC-3 | ||

|

|

|

||

| TFC-4 | TFV-5 | TFV-6 |

Classifications of Thermal Filaments

1. Point and Loop Heaters

2. Coil Heaters

3. Basket Heaters

4. Spiral Heaters

Applications of Thermal Filaments

1. Offer good heat transfer.

2. Mostly inert in contact with hot metals.

3. Evaporate metals do not wet alumina, resulting in the melt forming a "sphere" that acts as a point source.

4. Heat resistance does not change throughout the deposition since evaporant does not touch the underlying material.

5. Work well while thermally evaporating gold.