Sputtering Targets

Evaporation Materials

Evaporation Sources

High Purity Materials

Thin Film Substrates

Crytstal Materials

+86-731-89578196

+86-731-89578196

[email protected]

[email protected]

Sputtering Targets

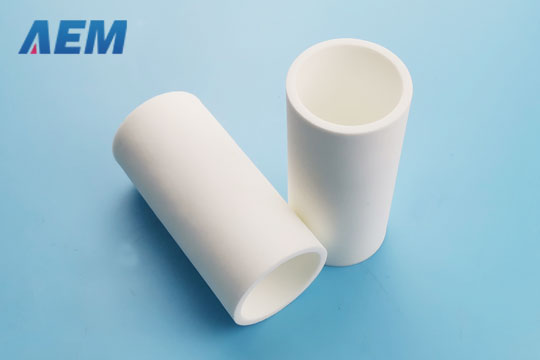

AEM Deposition is known for its expertise in manufacturing high-quality crucibles designed for various industrial applications, and our crucibles are meticulously crafted with a focus on extreme design, utilizing premium raw materials to ensure durability and longevity even under extreme temperature conditions. Our high-performance crucibles exhibit outstanding thermal shock resistance and chemical resilience, available in a comprehensive selection of standard dimensions as well as tailor-made configurations.

Crucible is a container designed to bear very high temperatures and often used in the laboratory to contain chemical compounds while heating up to extremely high temperatures. Crucibles come in several sizes and usually with a correspondingly-sized lid. There are several material options including alumina, quartz, graphite, silicon carbide, platinum, etc.. When choosing a crucible, consider the capacity, temperature range, and chemical compatibility to suit different applications and operating conditions. AEM Deposition commits to providing personalized solutions for our valuable customers. We are always here to help you and hope you can feel free to request a quote.

You can check the details information of specific category as below:

We offer a diverse type of crucibles in various materials, like Alumina, Zirconium, and Magnesium Oxide for diverse applications. Also, our crucibles are meticulously manufactured from high-purity materials, ensuring minimal impurities and superior resistance to chemical reactions. This purity is especially crucial in applications where contamination can affect the integrity of the deposition or melting process.

At AEM Deposition, we employ cutting-edge technology to provide crucibles with all kinds of materials and sizes that exceed your specific requirements. Recognizing the diverse needs of our customers ensures that our crucibles can be tailored to specific applications, meeting the unique requirements of different industries and research endeavors.

Crafted from high-purity materials, our crucibles are designed to ensure reliable performance even under extreme conditions. Our crucibles are rigorously quality-controlled to ensure consistent and reliable performance. Each crucible is thoroughly inspected to meet the highest industry standards, providing confidence in their performance and longevity.

Not sure what to choose? Our specialists can help. They know all about crucibles and can guide you to the best choice for your project. Our online service responds quickly within one hour, and the after-sales service is also very thoughtful in accordance with your requrements.

Crucible manufacturing involves multiple steps to guarantee the production of durable, high-quality vessels that can withstand extreme heat and harsh chemicals. It can be divided into ceramic crucibles, metal crucibles, and graphite crucibles in terms of different materials, and here's a brief introduction about three types of crucible production process:

Crafted from heat-resistant ceramics like alumina, zirconia, or silicon carbide, these are typically used in applications that demand resistance to high temperatures and chemical neutrality.

Material Selection: The choice of refractory ceramic material depends on the specific requirements of the crucible, such as alumina, zirconia, or silicon carbide.

Molding and Shaping: The prepared material is shaped into crucible molds through various molding techniques.

Sintering: For ceramic crucibles, the next step is firing or sintering. This process involves heating the crucible in a specialized furnace at high temperatures. It solidifies the material and gives the crucible its strength and thermal resistance.

Machining and Finishing: The formed crucibles may be machined to achieve precise dimensions and surface finishes, ensuring they meet the necessary specifications for their intended use.

Quality Control and Testing: Throughout the manufacturing process, strict quality control measures are implemented to ensure the crucibles meet the required standards. This includes testing for thermal conductivity, density, strength, and resistance to thermal shock. Only crucibles that pass these quality tests are deemed suitable for use.

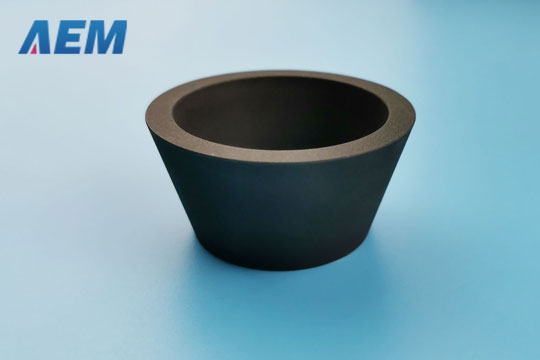

A graphite crucible, used for melting and casting non-ferrous metals like gold, silver, aluminum, and brass, is an ideal tool for metal casting.

Material Selection and Preparation: The first step is selecting high-quality graphite materials based on the desired properties and application requirements. Then, the chosen graphite materials are processed through several stages. They're crushed into a fine powder to ensure consistency and remove impurities. This graphite powder is then combined with binders and additives to improve its plasticity and moldability.

Molding: The ready-made graphite blend is formed into crucible molds using different molding techniques. The most common technique is isostatic pressing, where the graphite powder is put into a flexible mold and exposed to high-pressure isostatic compression. This method guarantees consistent density and strength across the crucible.

Carbonization: After molding, the crucible-like graphite undergoes carbonization. The crucibles are heated to a specific temperature, usually around 1000°C, in a controlled environment. This process eliminates the binders, transforming the molded graphite into a solid carbon structure.

Graphitization: The carbonized crucibles are subjected to graphitization, a high-temperature process. They are heated in a specialized furnace to temperatures exceeding 2500°C. This procedure converts the carbon structure into graphite, improving its thermal conductivity and other beneficial properties.

Polishing and Finishing: Once graphitized, the crucibles are subjected to post-processing procedures to guarantee their ultimate quality. This involves machining, polishing, and inspection to eliminate surface flaws, and achieve precise dimensions.

Quality Control: Throughout the manufacturing process, strict quality control measures are implemented to ensure the crucibles meet the required standards. This includes testing for thermal conductivity, density, strength, and resistance to thermal shock. Only crucibles that pass these quality tests are deemed suitable for use.

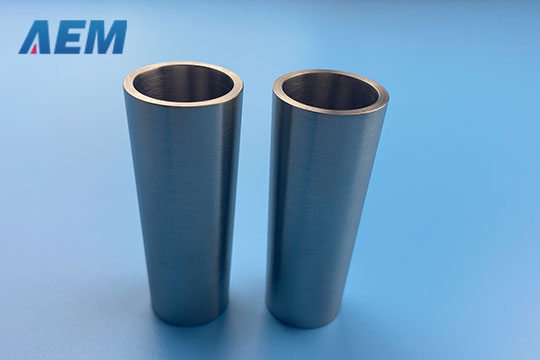

A metal crucible is a container made from a metallic material, typically a metal or metal alloy, such as platinum, tantalum, and copper, designed to withstand high temperatures. Let's take tungsten crucibles as an example:

Material Selection: The process starts by choosing top-notch tungsten powder. As a refractory metal with a high melting point, tungsten is ideal for applications that involve extreme temperatures.

Isostatic Pressing: Isostatic pressing is a method used to mold tungsten powder into a pre-sintered compact of the desired shape. This process involves placing the tungsten powder in a flexible mold, then applying equal pressure from all sides with a fluid, either liquid or gas, to form the powder into the crucible's shape.

Mechanical & Processing: The green compact from isostatic pressing is mechanically processed. This involves machining or shaping the compact to reach the final dimensions and desired characteristics of the tungsten crucible. Techniques like turning, milling, or grinding may be employed.

IF (Induction Frequency) Induction Sintering: The green compact is then processed through IF induction sintering. This method heats the compact in a high-frequency electromagnetic field, causing the tungsten powder particles to fuse, creating a dense, solid structure. Sintering is vital to attain the desired strength and density in the tungsten crucible.

Mechanical Processing: After sintering, the crucible is further mechanically processed. This crucial step refines the surface finish, guarantees dimensional precision, and adheres to specific tolerances. Depending on the requirements, this could include machining or finishing processes.

Quality Control: Quality control tests are conducted to confirm the tungsten crucible meets set standards, including dimensional checks and visual inspections. The aim is to detect and address any flaws or discrepancies from the required specifications.

Choosing the right crucible is essential for optimal results in manufacturing processes. Factors to consider include the material being melted or analyzed, operating temperature range, and desired level of chemical resistance.

1. Different materials require different types of crucibles; for example, graphite crucibles are ideal for non-ferrous metals, while ceramic crucibles are better for high-purity materials. High-temperature applications may require crucibles made from materials like silicon carbide or tantalum.

2. Determine the maximum temperature your process will reach. Crucibles are made from materials with varying temperature resistance.

3. It's also important to consider chemical resistance because some materials may react with certain chemicals or corrode under specific conditions. Crucible made from materials like platinum, quartz, or zirconia may be more suitable for corrosive materials. Choosing the right crucible ensures efficient, reliable manufacturing processes that produce high-quality results.

Crucibles have a wide range of applications across various industries due to their ability to bear high temperatures and hold molten materials. Some common applications of crucibles include:

Due to their resistance to high temperature and remarkable strength, crucibles are widely used in e-beam evaporation, thermal evaporation deposition, and crystal growth, especially tungsten and molybdenum crucibles are widely applied in single crystal growths.

Crucibles are extensively used in metallurgical processes for melting and casting metals.

Crucibles are employed in laboratories to heat and process substances at high temperatures, facilitating reactions and analytical procedures.

In material science and engineering, crucibles are used for testing the properties of materials under extreme heat conditions. This includes studies on melting points, phase transitions, and material behavior at elevated temperatures.

Component Manufacturing: Crucibles are used in the production of certain electronic components, such as the melting and casting of metals for semiconductor manufacturing.

When you're looking to buy a crucible, here are some key points to keep in mind:

When you're looking to buy a crucible, here are some key points to keep in mind:

Verify the purity level of the material used in the crucible, especially for special uses like in electronics. Check the specifications provided by the manufacturer for details on purity.

Consider the size and capacity requirements for your application. Crucibles are available in various materials, shapes and sizes, and choosing the right dimensions is essential for optimizing performance and efficiency in your processes.

Ensure the crucible material is compatible with the substances it will come into contact with during processing.

Understand the specific requirements of your application. Ensure that the chosen crucible aligns with the intended use.

Check if the supplier offers customization options for crucibles. Depending on your application, you may require specific features or modifications in terms of shape, size, or other characteristics. Customization can ensure that the crucible meets your exact needs.

Check the delivery times and lead times of your crucibles, especially if you have time-sensitive projects. Ensure that the supplier can meet your required timelines and has a reliable shipping process.

Always use tongs that fit well when handling different types of crucibles. Using the wrong tongs can damage the crucible or even cause it to fail at the most inconvenient time.

Before heating, place a cardboard disk between the crucible and the furnace base. It will burn off, leaving a carbon layer that prevents the crucible from sticking to the furnace bottom. Alternatively, a Plumbago (Carbon Black) coating can serve the same purpose.

Use separate crucibles for each metal type to prevent contamination. Always empty the crucible after use. Leftover metal can expand when reheated and ruin the crucible.

Please temper new crucibles or those that have been stored. Warm the empty crucible for 2 hours at 220 F (104 C), ensuring proper ventilation as new crucibles will smoke while the glaze sets. Next, heat the empty crucible until it glows red. Let the crucible cool down to room temperature inside the furnace before using it. This process should be applied to ALL new crucibles and any crucible that might have been exposed to moisture while in storage.

Keep all crucibles in a dry place. Moisture can lead to cracking when heated. If stored for a long period, re-tempering is recommended.

Silicon carbide crucibles, which are least prone to water absorption during storage, usually don't require tempering before use. However, it's advisable to heat a new crucible to a red-hot temperature before its initial use to eliminate and solidify factory coatings and binders.

AQuartz Crucible and Ceramic Crucible have different temperature resistance and acid-alkali resistance. The following things are details:

Quartz Crucible are available in milky white and transparent varieties. Milky white crucible is used below 1200 degrees Celsius, while transparent crucible are used below 1400 degrees Celsius. Ceramic Crucible is used between 1400 and 1600 degrees Celsius.

Quartz Crucible is resistant to acids and alkalis. It is durable and maintains its integrity when exposed to various chemical environments. However, it's essential to note that Quartz Crucible should not be used with hydrofluoric acid. Ceramic Crucible also demonstrates resistance to acids and alkalis, but its performance in aggressive chemical environments may vary based on the specific type of ceramic material used. Care should be taken to select the appropriate ceramic composition based on the chemical conditions of the application.

Ceramic crucibles, graphite crucibles and metal crucibles differ in terms of their properties and suitable applications:

Generally, ceramic crucibles and metal crucibles have lower thermal conductivity compared to graphite crucibles. And metal crucibles typically exhibit greater thermal conductivity than ceramics. This means that ceramic crucibles may take longer to heat up and cool down.

Typically chemically inert and corrosion-resistant, ceramic crucibles are ideal for applications where potential reactions with the crucible material are a concern. While graphite is generally resistant to most chemicals, it can react with specific gases or substances, particularly at high temperatures. And depending on the metal or alloy used, metal crucibles may be susceptible to corrosion or chemical reactions with certain substances. Some metals, like stainless steel, are more corrosion-resistant than others.

Renowned for withstanding temperatures over 3000°C, ceramic crucibles are ideal for high-heat processes such as metal casting and glass melting. However, the specific graphite type and material impurities can affect their performance. While the temperature resistance of metal crucibles depends on the specific metal or alloy used. and many metals can withstand high temperatures, they may have limitations compared to graphite in certain extreme conditions. For applications requiring extremely high temperatures, ceramic crucibles might be slightly superior.

Graphite crucibles are durable and resistant to thermal shock. However, they can be brittle and may be more susceptible to physical damage compared to metals. Also, ceramic crucibles are more prone to cracking or chipping if subjected to mechanical stress. While metals are generally more ductile and malleable, making metal crucibles more resistant to mechanical stress and physical damage.

Ceramic Crucibles are commonly used in applications requiring chemical corrosion resistance and high-temperature stability, like in the analysis of minerals, metals, and ceramics. While graphite crucibles are popular in metallurgical applications, jewelry crafting, and procedures involving high temperatures, such as metal and alloy melting. And metal crucibles are typically used in applications depending on the specific metal or alloy and requiring durability. For example, stainless steel crucibles are used in laboratory and industrial settings, while platinum crucibles may be used in high-precision applications.

Solution about Crucible? Our experts are here to help. Contact us for advice on choosing and using crucible.

Get a quote now or let us know what you’re looking for and we will get back to you soon!

crucible is needed to withstand the extreme temperatures encountered in melting metals. The crucible material must have a much higher melting point than that of the metal being melted and it must have good strength even when white hot. Crucible is traditionally made from ceramic materials, which can withstand very high temperatures. It may also be made of steel or iron to melt softer metals such as aluminum and zinc because these metals melt at a temperature below that of the crucible material.

It depends on the material of the crucible and the application. Some crucibles are designed for single-use, while others can be reused multiple times. Factors such as thermal shock resistance and mechanical strength play a role in determining whether a crucible is suitable for reusing.

The choice of crucible material for melting metal depends on the type of metal and the temperature of the process. Graphite crucibles are commonly used for melting non-ferrous metals, while high-purity alumina or ceramic crucibles may be suitable for certain applications.

It depends on the compatibility of the crucible material with the substances you are working with. Some crucibles are versatile and can be used for different materials, while others may be specific to certain applications. Cross-contamination and chemical reactions should be considered.

Store crucibles in a clean, dry environment, and follow any specific storage recommendations provided by the manufacturer. Avoid stacking crucibles if they are susceptible to chipping or breakage.

Firstly, all debris must be removed from the crucible before the cleaning process, which can be done by a variety of tools, such as steel wool, scrapers, and/or wire brushes.

Next, cool the crucible to prevent residual heat from causing damage during cleaning. Then, prepare a hot water and detergent mixture to clean the crucible's interior. Also, wipe the exterior surfaces with a soft cloth or scrub brush, and dry them using compressed air or a lint-free cloth.

For optimal performance and durability, adhere to the manufacturer's guidelines on preheating and usage. By practicing appropriate care and maintenance, crucibles can deliver dependable and uniform performance across various applications.

Bank Wire Transfer: Direct bank transfers are a secure and widely used method. Details for wire transfers will be provided on the invoice.

PayPal: For added flexibility, PayPal payments are often accepted. This option is ideal for those who prefer online payment gateways.

Letter of Credit (L/C): In certain cases, we may accept payment through a letter of credit, offering a secure method for international transactions.

We use UPS or DHL or FedEx express for most of countries. Please let us know if you have their account number. We can ship the items out by using your account number. We use IPS express for Iran, Iraq and UAE. We will by sea or air if the weight or volume is large.

Usually delivery time is around 4-5 weeks. The lead time varies based on quantity and material, ranging from 1 to 4 months.