Sputtering Targets

Evaporation Materials

Evaporation Sources

High Purity Materials

Thin Film Substrates

Crytstal Materials

+86-731-89578196

+86-731-89578196

[email protected]

[email protected]

Sputtering Targets

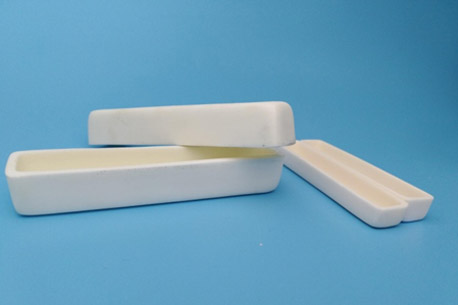

Alumina Crucible is made from alumina, also known as aluminum oxide( AI2O3). Alumina is an ideal ceramic material with high-temperature resistance, chemical stability, and mechanical strength, making it suitable in the form of crucibles and their covers for high-temperature working conditions that demand contamination-free results.

AEM offers high-quality Al2O3 crucibles with good electrical insulation, excellent corrosion resistance, and excellent thermal shock properties, and also available in many sizes and shapes.

We can provide alumina crucibles in various shapes and sizes to meet your needs, including rectangular, cylindrical, and other specially shaped crucibles. The volume range we offer is from 1 to 2000ml, and the maximum working temperature of our alumina crucibles can be up to 1800℃ or 3180°F.

Purity: 99%, 99.3%, 99.5%

Color: White/Ivory

Density: 3.98 g/cm³

Melting Point: 2020℃

| Top Diameter | Bottom Diameter | Height | Thickness | Volume |

|---|---|---|---|---|

| 48 mm | 30 mm | 54 mm | 3 mm | 50 ml |

| 79 mm | 42 mm | 93 mm | 3 mm | 150 ml |

| 100 mm | 60 mm | 116 mm | 3 mm | 500 ml |

| 125 mm | 82 mm | 148 mm | 3 mm | 1000 ml |

| Length | Width | Height | Thickness | Volume |

|---|---|---|---|---|

| 60 mm | 30 mm | 20 mm | 3 mm | 20 ml |

| 90 mm | 60 mm | 45 mm | 3 mm | 200 ml |

| 100 mm | 100 mm | 40 mm | 4 mm | 300 ml |

| 160 mm | 160 mm | 45 mm | 7 mm | 800 ml |

The dimensions offered above are just for reference. We provide customized alumina crucibles upon your requirements for various sizes and shapes. We also offer crucible covers at an additional cost to meet your needs.

AEM's alumina crucibles are known for their remarkable purity, meeting strict criteria for chemical inertness and minimal contamination.

We are committed to high-quality alumina crucibles by rigorous inspection at every manufacturing process, ensuring that our alumina crucibles consistently adhere to precise specifications, delivering reliable and high-performance solutions for a variety of applications.

Understanding the varied requirements of our clients, we can offer customized solutions to precisely meet the unique needs across specific applications.

Our experienced team works closely with clients by offering expert assistance and guidance within 24 hours against your problems and needs.

At AEM, we offer high-purity alumina powder as raw material, providing the basis for creating the crucible's structure.

Using cutting-edge pressing techniques, our alumina powder can be molded into your desired shapes with precision.

We use advanced technology for sintering process. The temperature and duration of the sintering process are carefully controlled to achieve the desired properties.

After sintering, the crucible may undergo additional finishing processes, such as grinding or polishing, to achieve the desired surface finish and dimensional accuracy.

We employ rigorous quality control measures throughout the production process to ensure they meet specific standards. This includes dimensional checks, surface roughness, visual inspection and testing for purity, mechanical strength, and other critical properties.

Due to their thermal stability, chemical inertness, and adaptability, alumina crucibles are integral parts for achieving controlled and precise outcomes in a variety of laboratory and industrial applications in solutions evaporation, concentration and crystallization. Their high thermal stability allows for the gradual evaporation of solvents, contributing to the concentration of the solutes in the solution. And alumina crucibles provide a chemically inert and thermally stable environment, allowing for controlled concentration without the risk of contamination. The high purity of alumina prevents contamination of the crystalline product, making it indispensable in industries such as materials science, where the quality of the crystals is crucial.

Alumina crucibles play a significant role in semiconductor manufacturing processes. Their impressive purity levels ensure minimal contamination, making them suitable for applications where even slight impurities can affect electronic components. Alumina crucibles provide a chemically inert and controlled environment for processes critical to semiconductor fabrication.

Alumina crucibles are widely used in laboratories for a range of experiments, including sample preparation, chemical analysis, and material synthesis. Their chemical inertness and ability to withstand high temperatures make them suitable for various research applications.

With their thermal stability and resistance to chemical reactions, alumina crucibles are an integral part in glass manufacturing processes, particularly in the melting and processing of glass materials at elevated temperatures.

Alumina crucibles are widely used in metallurgical processes for melting and processing metals and alloys at high temperatures. They play a crucial role in metal casting, alloy production, and other metallurgical applications.

Alumina crucibles can withstand sudden and drastic changes in temperature without cracking, maintaining their structural integrity even under extreme temperature conditions.

Alumina is chemically inert, preventing reactions with various molten metals and corrosive materials, maintaining the purity of processed substances.

The melting point of alumina (approximately 2020℃) is significantly higher than that of many metals. This high-temperature resistance makes alumina crucibles suitable for applications involving the melting and processing of materials at elevated temperatures,

Alumina has high hardness with excellent wear resistance, making that the crucibles maintain their structural integrity and surface quality, even under demanding conditions.

Alumina crucibles are relatively lightweight and easy to handle, simplifying the loading, unloading, and manipulation processes in laboratories and industrial settings.

When purchasing alumina crucibles, several important considerations should be taken into account to ensure that the selected crucibles meet the specific needs of your application. Here are some key considerations:

The purity level is important for your choice of purchasing alumina crucibles. High-purity alumina is essential for applications requiring minimal contamination, such as semiconductor manufacturing and certain laboratory processes.

Verify the chemical compatibility of the alumina crucibles with the substances they will come into contact with during your processes. The choice of crucibles will depend on the chemicals to be used.

Determine the appropriate size and shape of the crucibles for your intended use. Consider the volume of material you'll be working with and the dimensions required for your equipment or processes.

Check if the manufacturer offers customization options. Customization allows for a better fit to your unique requirements.

Confirm the availability of the alumina crucibles and inquire about the delivery time. This is particularly important if your project has specific timelines or deadlines.

Proper care and maintenance of alumina crucibles are essential to ensure their longevity and performance in high-temperature applications. Here are some guidelines for the care and maintenance of alumina crucibles:

After each use, clean the alumina crucible thoroughly to remove any residual materials. Using appropriate tools for cleaning such as a soft brush or sponge can help protect the crucible from damage.

Alumina crucibles have good thermal shock resistance, but it's still advisable to avoid rapid and extreme temperature changes. Gradual heating and cooling help to minimize the risk of thermal shock.

Handle alumina crucibles with care to prevent physical damage. Avoid dropping or impacting the crucible against hard surfaces, as this can lead to cracks or fractures.

Store alumina crucibles in a dry and clean environment. Avoid stacking or placing heavy objects on top of them to prevent potential breakage or deformation.

When loading and unloading materials from the crucible, use appropriate tools to minimize the risk of physical damage. Avoid using sharp objects that could scratch or compromise the crucible's integrity.

Regularly inspect alumina crucibles for any signs of damage, such as cracks or chips. If any damage is observed, consider replacing the crucible to maintain the integrity of your experiments or processes.

It is essential to adhere to the care and maintenance guidelines provided by the manufacturer of the alumina crucibles. Following these instructions diligently ensures the optimal performance and longevity of the alumina crucibles, taking into account the unique characteristics and requirements set by the manufacturer.

Request a Alumina Crucible Quote for Your Projects Now

Solution about Alumina Crucible? Our experts are here to help. Contact us for advice on choosing and using Alumina Crucibles.

Get a quote now or let us know what you’re looking for and we will get back to you soon!

The maximum working temperature of our alumina crucibles can be up to 1800℃ or 3180°F.

Yes, we can provide customization in various sizes and shapes to meet your specific needs.

Store alumina crucibles in a clean and dry environment. Consider using protective packaging or containers to prevent potential damage during storage, which can ask for the guidelines for specific storage recommendations related to the alumina crucibles you are using.

Yes, quality control measures are an integral part of the manufacturing process for our alumina crucibles to ensure that they meet unique requirements and perform reliably. And we also adhere to industry-specific quality standards to producing high-quality alumina crucibles.

Yes, alumina crucibles can be reused if they are properly cleaned and maintained.

Just send us inquiries, our team will prepare an official quote for you. If you are satisfied with our products and quotes, you can send us PO or we will send you PI for purchasing.

Bank Wire Transfer: Direct bank transfers are a secure and widely used method. Details for wire transfers will be provided on the invoice.

PayPal: For added flexibility, PayPal payments are often accepted. This option is ideal for those who prefer online payment gateways.

Letter of Credit (L/C): In certain cases, we may accept payment through a letter of credit, offering a secure method for international transactions.

We use UPS or DHL or FedEx express for most of countries. Please let us know if you have their account number. We can ship the items out by using your account number. We use IPS express for Iran, Iraq and UAE. We will by sea or air if the weight or volume is large.

Usually delivery time is around 4-5 weeks. The lead time varies based on quantity and material, ranging from 1 to 4 months.