Sputtering Targets

Evaporation Materials

Evaporation Sources

High Purity Materials

Thin Film Substrates

Crytstal Materials

+86-731-89578196

+86-731-89578196

[email protected]

[email protected]

Sputtering Targets

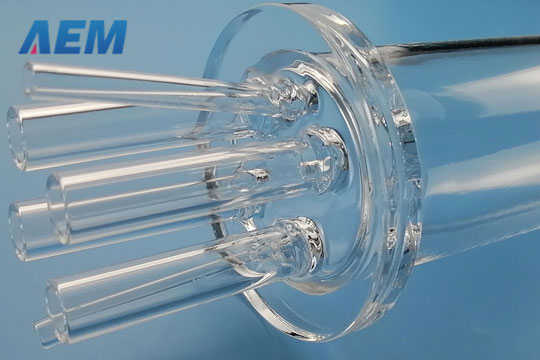

Quartz crucibles, made from a crystalline form of silicon dioxide (SiO2), are specialized containers designed for handling and processing materials at high temperatures. The quartz crucible is divided into transparent and opaque quartz crucibles. The semi-transparent quartz crucible is made by arc melting method of high purity quartz sands, which is an indispensable part for growing single crystal ingots in the semiconductor and solar industries.

AEM offers high-purity SiO2 crucibles with strong temperature resistance and good thermal insulation for your unique projects, and provide customization options to meet your specific needs for diverse applications.

We offer quartz crucibles in various shapes and sizes to meet your needs, including rectangular, cylindrical, squared, and other specially shaped crucibles. The volume range we offer is from 1 to 2000ml, and the maximum working temperature of our quartz crucibles can be up to 1600℃ or 2912 °F.

Purity: 99.99%

Type: Transparent and Opaque

Color: White/Transparent

Density: 2.2~2.3 g/cm³

Melting Point: 1710℃

| Type | D (mm) | H(mm) | W1(mm) | W2(mm) | W3(mm) | R1(mm) | R2(mm) |

|---|---|---|---|---|---|---|---|

| 14inch | 355±3 | 240±3 | 10±2 | 10±2 | 11±2 | 381 | 89 |

| 20inch | 505±3 | 385±3 | 11±2 | 11±2 | 11±2 | 508 | 120 |

| 26inch | 654±3 | 500±3 | 12+3/-1 | 12+3/-1 | 14+4/-2 | 660 | 120 |

| 32inch | 810±3 | 680±3 | 15±3 | 15±3 | 21±4 | 812 | 120 |

| 40inch | 1016±4 | 760±3 | 15±3 | 15±3 | 25±5 | 1016 | 160 |

The dimensions offered above are just for reference. We can provide a variety of quartz crucibles in different sizes (height, outside diameter, wall thickness) and shapes according to your specific requirements.

| Grade | Al | Fe | Ca | Na | K | Li | Ti | Cr | Ni | Mg | B | P | OH |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Solar Grade | 18 | 0.2 | 0.6 | 1.1 | 0.9 | 0.7 | 1.1 | 0.2 | 0.6 | 0.05 | 0.08 | 0.05 | 50 |

| Electronics Grade | 7.5 | 0.2 | 0.5 | 0.3 | 0.1 | 0.9 | 1.4 | 0.2 | 0.5 | 0.05 | 0.04 | 0.02 | 50 |

| Synthetic | 20 | 27 | 23 | 8 | 1 | 1 | 25 | 27 | 23 | 9 | 10 | 10 | 50 |

AEM's quartz crucibles are known for their remarkable purity, meeting strict criteria for chemical inertness and minimal contamination.

We are dedicated to top-quality quartz crucibles by rigorous inspection at every manufacturing process, ensuring that our quartz crucibles consistently meet specific industry needs, delivering reliable and high-performance solutions for various applications.

Whether various crucible size, shape, transparency or not, our comprehensive customization ensures quartz crucibles can be tailored to specific requirements.

Our experienced team works closely with clients by offering expert assistance and guidance in choosing the most suitable quartz crucibles for their projects.

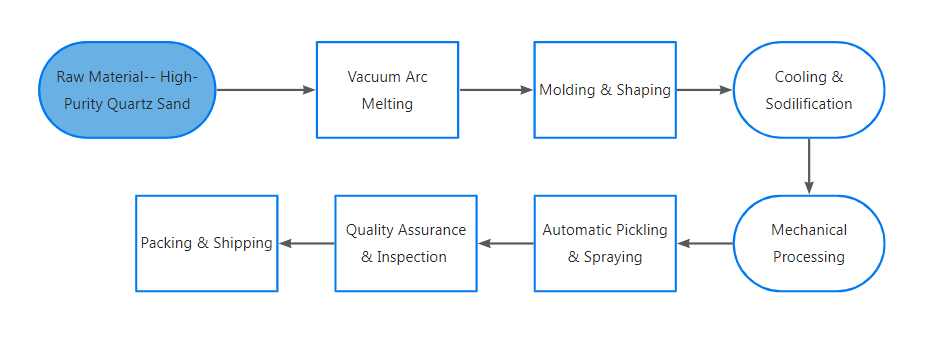

The preparation of quartz sand of AEM Deposition begins with the selection of premium-quality quartz, followed by advanced purification techniques to achieve a high level of purity.

AEM Deposition uses advanced arc melting method to provide high temperature and efficient energy, contributing to better quartz quality and energy consumption.

Using precision molds to shape the molten quartz into your desired form. Our technology excels in producing complex geometries with excellent precision.

We employ controlled cooling and solidification techniques to ensure the formation of a strong and uniform structure.

AEM Deposition offers specialized mechanical processing, including grinding, cutting, and cleaning. We focus on extreme specifications and quality in every step.

We utilize an automated pickling and spraying system to enhance our quartz crucibles' surface and remove impurities, ensuring precise quality.

The quartz crucible will be securely packed in a wooden case, cushioned with soft materials, to prevent any movement within the case.

Quartz crucibles are extensively used in the refining of precious metals and special alloys. The high thermal stability and chemical inertness of quartz make it an ideal material for containing and processing valuable metals during refining processes. Crucibles are used to melt, refine, and alloy metals like gold, silver, platinum, and specialized alloys in jewelry and metallurgical industries.

In the lamp industry, particularly for the production of phosphorescent or fluorescent powders, quartz crucibles are used for calcination processes. The high temperatures required for these calcination processes are well within the thermal stability range of quartz, and the inert nature of quartz prevents contamination of the powders during processing.

Quartz crucibles find applications in the calcination of alumina (aluminum oxide). Alumina calcination involves subjecting alumina to high temperatures to drive off moisture and other volatile components. Quartz crucibles provide a clean and stable environment for this process due to their chemical inertness and resistance to high temperatures.

Quartz crucibles are widely used in laboratories for various applications. Their chemical inertness makes them suitable for handling a wide range of chemicals without contamination. Quartz crucibles are employed in experiments involving high temperatures, chemical reactions, and sample preparations in diverse scientific disciplines.

In the chemical industry, quartz crucibles are utilized for processes related to rare earth production. Rare earth elements often require controlled environments for purification, separation, and processing. Quartz crucibles, with their resistance to chemical reactions and high temperatures, provide an ideal vessel for these critical chemical processes.

Quartz crucible has a high melting point of around 1,710°C. This property enables to withstand extremely high temperatures encountered.

Quartz crucibles are chemically inert and resistant to many corrosive substances, minimizing contamination and ensuring the purity of the processed materials.

Quartz is an excellent electrical insulator, making quartz crucibles suitable for applications involving high-temperature electrical heating or where electrical insulation is required.

Quartz crucibles are known for their durability and long lifespan, providing a cost-effective solution over time.

Quartz crucibles exhibit excellent thermal stability, maintaining their structural integrity and dimensional stability at high temperatures.

Transparent quartz crucibles offer optical transparency, allowing for visual observation and monitoring of processes.

Quartz surfaces usually display non-wetting properties, facilitating easy removal of the processed materials and reducing contamination.

When ordering quartz crucibles, it's essential to consider various factors to ensure that you select the right product for your specific application. Here are some key considerations to keep in mind:

Understand the specific requirements of your application. Different industries and processes may have distinct needs, such as semiconductor manufacturing, metallurgy, or laboratory experiments. Ensure that the chosen quartz crucible aligns with the intended use.

Verify the purity level of the quartz material used in the crucible. High-purity quartz minimizes the risk of contamination in sensitive applications, such as semiconductor manufacturing or crystal growth. Check the specifications provided by the manufacturer for details on purity.

Assess the types of chemicals and substances that will come into contact with the quartz crucible. Choose a crucible with high chemical inertness to resist reactions with acids, bases, and other corrosive materials relevant to your application.

Consider the size and shape requirements for your application. Quartz crucibles are available in various shapes and sizes, and choosing the right dimensions is essential for optimizing performance and efficiency in your processes.

Check if the supplier offers customization options for quartz crucibles. Depending on your application, you may require specific features or modifications in terms of shape, size, or other characteristics. Customization can ensure that the crucible meets your exact needs.

Check the delivery times and lead times of quartz crucibles, especially if you have time-sensitive projects. Ensure that the supplier can meet your required timelines and has a reliable shipping process.

Melting Point: Quartz crucibles have a melting point around 1,710°C, while tungsten crucibles have an extremely high melting point of 3,422°C.

Thermal Conductivity: Quartz has relatively lower thermal conductivity than tungsten, advantageous in processes where controlled heating or thermal insulation is desired.

Chemical Inertness: Quartz is chemically inert and highly resistant to most acids, alkalis, and corrosive chemicals, while tungsten can react with certain chemicals at high temperatures or in aggressive environments.

Mechanical Properties: Quartz is relatively brittle and may be more prone to breakage compared to metals like tungsten.

Cost: Quartz crucibles are generally more affordable compared to tungsten crucibles, especially in smaller sizes.

The maximum working temperature of our quartz crucibles can be up to 1600 ℃ or 2912 °F.

Yes, we can provide customization in various sizes and shapes to meet your specific needs.

Yes, quartz crucibles are often reusable, provided they are properly maintained and not subjected to extreme conditions that may compromise their structural integrity.

Quartz crucibles can be cleaned using methods suitable for glassware, such as rinsing with deionized water or mild acids. Avoid harsh chemicals that may react with quartz. Proper handling, avoiding thermal shock, and following recommended cleaning procedures contribute to maintenance.

Just send us inquiries, our team will prepare an official quote for you. If you are satisfied with our products and quotes, you can send us PO or we will send you PI for purchasing.

Bank Wire Transfer: Direct bank transfers are a secure and widely used method. Details for wire transfers will be provided on the invoice.

PayPal: For added flexibility, PayPal payments are often accepted. This option is ideal for those who prefer online payment gateways.

Letter of Credit (L/C): In certain cases, we may accept payment through a letter of credit, offering a secure method for international transactions.

We use UPS or DHL or FedEx express for most of countries. Please let us know if you have their account number. We can ship the items out by using your account number. We use IPS express for Iran, Iraq and UAE. We will by sea or air if the weight or volume is large.

Usually delivery time is around 4-5 weeks. The lead time varies based on quantity and material, ranging from 1 to 4 months.

Request a Quartz Crucible Quote for Your Projects Now

Solution about Quartz Crucible? Our experts are here to help. Contact us for advice on choosing and using Quartz Crucibles.

Get a quote now or let us know what you’re looking for and we will get back to you soon!