Sputtering Targets

Evaporation Materials

Evaporation Sources

High Purity Materials

Thin Film Substrates

Crytstal Materials

+86-731-89578196

+86-731-89578196

[email protected]

[email protected]

Sputtering Targets

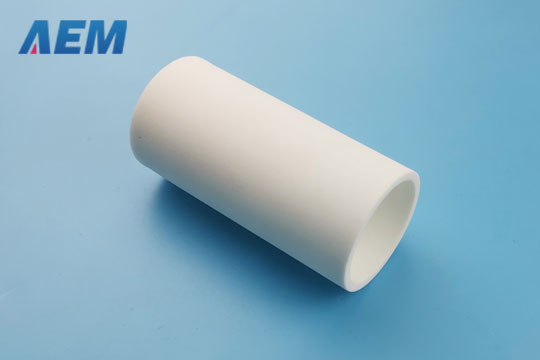

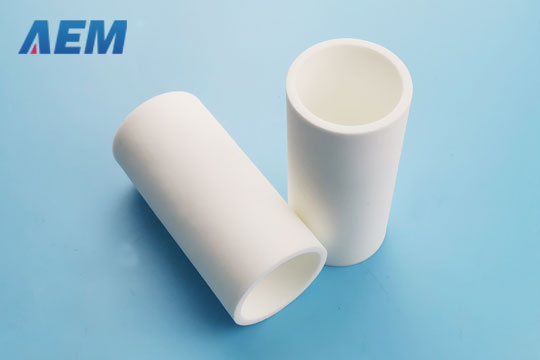

Magnesium Oxide (MgO) crucibles, containers made of magnesium oxide, are used for high-temperature applications due to their superior thermal stability, chemical resistance, and minimal reactivity with molten substances. It is an excellent alternative material to Alumina (Al2O3) crucibles because of its superior chemical resistance and its inertness to metals, slags, and superconductor compounds.

AEM offers top-quality MgO crucibles with high thermal conductivity and low electrical conductivity for your unique applications, and provide tailor-made solutions to meet your requirements.

We can provide magnesium oxide crucibles in various shapes and sizes to meet your needs, including rectangular, cylindrical, squared, and other specially shaped crucibles. The volume range we offer is from 1 to 2000ml, and the maximum working temperature of our magnesium oxide crucibles can be up to 2200℃ or 4000 °F.

Purity: >99%

Color: White

Density: 3.56-3.65 g/cm3

Melting Point: 2800℃

| Top Diameter | Bottom Diameter | Height | Thickness | Volume |

|---|---|---|---|---|

| 48 mm | 30 mm | 54 mm | 3 mm | 50 ml |

| 79 mm | 42 mm | 93 mm | 3 mm | 150 ml |

| 100 mm | 60 mm | 116 mm | 3 mm | 500 ml |

| 125 mm | 82 mm | 148 mm | 3 mm | 1000 ml |

| Length | Width | Height | Thickness | Volume |

|---|---|---|---|---|

| 60 mm | 30 mm | 20 mm | 3 mm | 20 ml |

| 90 mm | 60 mm | 45 mm | 3 mm | 200 ml |

| 100 mm | 100 mm | 40 mm | 4 mm | 300 ml |

| 160 mm | 160 mm | 45 mm | 7 mm | 800 ml |

The dimensions offered above are just for reference. We can provide a variety of magnesium oxide crucibles in different sizes and shapes to meet your specific needs for various applications.

AEM ensures high-quality MgO crucibles, featuring a pure composition, outstanding thermal stability, and remarkable chemical inertness.

We are dedicated to top-quality MgO crucibles by rigorous inspection at every manufacturing process, ensuring that our MgO crucibles consistently meet unique specifications, delivering reliable and high-performance solutions for various applications.

Whether various crucible size, shape, or other specifications, our comprehensive customization ensures MgO crucibles can be tailored to specific requirements.

Our experienced team works closely with clients by offering comprehensive assistance and guidance in choosing the most appropriate MgO crucibles for their specific applications.

AEM Deposition begins by sourcing high-purity MgO powder, ensuring that the raw material meets strict quality standards.

Using cutting-edge pressing techniques, our magnesium oxide powder can be molded into your desired shapes with precision.

We use advanced technology for sintering process. The temperature and duration of the sintering process are carefully controlled to achieve the desired properties.

After sintering, the crucible may undergo additional finishing processes, such as grinding or polishing, to achieve the desired surface finish and dimensional accuracy.

We take rigorous quality control measures throughout the manufacturing process to ensure they meet or exceed specific standards. This includes dimensional checks, surface roughness, visual inspection and testing for purity, mechanical strength, and other critical properties.

The magnesium oxide crucible will be securely packed in a wooden case, cushioned with soft materials, to prevent any movement within the case.

In certain semiconductor manufacturing processes, MgO crucibles are used for high-temperature treatments, such as annealing or sintering, during the production of semiconductor devices.

Magnesium oxide crucibles are specifically designed for protecting ceramic products like β-Al2O3 from corrosion and volatility at high temperatures.

MgO crucibles are essential in producing dielectric materials like ceramics and thin films, and also crucial in the production of components for sensors, actuators, and transducers. Additionally, MgO crucibles are used to create pyroelectric materials that generate electric charges in response to temperature changes.

MgO crucibles stand as indispensable tools in ensuring the reliability and integrity of the final nickel-based super alloy products, facilitating the creation of high-performance alloys with superior mechanical and thermal properties.

The ability to withstand high temperatures, resist chemical reactions, and provide a controlled processing environment makes MgO crucibles essential for ensuring the integrity, purity, and safety of plutonium and uranium related material processing operations.

MgO crucibles has a high melting point of approximately 2,800°C, making it suitable for use in applications involving extreme temperatures.

MgO crucibles exhibit excellent chemical inertness, resisting attack from most acids, alkalis, and molten metals, ideal for handling corrosive materials in various industrial processes.

MgO crucibles have relatively lower thermal conductivity than graphite or silicon carbide, advantageous in processes where controlled heating or thermal insulation is desired.

MgO is an electrical insulator, making MgO crucibles suitable for applications involving high-temperature electrical resistance heating or where electrical insulation is required.

MgO surfaces usually display non-wetting properties, preventing molten metals and other substances from sticking to the crucible walls.

MgO crucibles are compatible with oxidizing atmospheres, suitable for applications where controlled oxidation is desired or where exposure to oxygen is unavoidable.

When purchasing magnesium oxide crucibles, several important considerations should be taken into account to ensure that the selected crucibles meet the specific needs of your application. Here are some key considerations:

The purity level is important for your choice of purchasing magnesium oxide crucibles, ensuring that the crucibles meet industry standards and are manufactured using high-quality materials to guarantee consistent performance.

Consider the compatibility of MgO crucibles with the materials you will be processing. While MgO is chemically inert in many cases, compatibility with specific chemicals and materials should be verified to prevent reactions that could affect your process.

Specify the required size and shape of the crucibles based on the volume and dimensions of your materials.

Check if the manufacturer offers customization options, such as special coatings or modifications, to meet specific requirements unique to your application.

Confirm the lead time for the production and delivery of the MgO crucibles. Ensure that the supplier can meet your timeline requirements, especially if your project has time-sensitive aspects.

Alumina Crucible

MgO Crucible

MgO crucibles have a better chemical resistance than that of alumina. MgO crucibles are usually inert to metals, slags, and superconductor compounds. In the synthesis or sintering of lithium solid-state electrolyte, MgO crucibles have the distinct advantage of not reacting with lithium, unlike alumina crucibles. Besides, alumina can react with alkaline substances.

MgO crucibles, with a higher melting point of 2800℃ compared to alumina crucibles at 2020℃, are ideal for ultrahigh-temperature processes up to 2200°C.

Alumina crucibles, with a Mohs hardness of 9, are harder than MgO crucibles, which have a hardness ranging from 5.5 to 6.5.

AEM Deposition is a reputable manufacturer and trusted source of top-quality magnesium oxide crucibles. Comprehensive services we offered makes us the first choice for superior-quality magnesium oxide crucibles. Trust AEM Deposition to meet your specified needs with excellence and precision.

The maximum working temperature of our magnesium oxide crucibles can be up to 2200℃ or 4000 °F.

Yes, we can provide customization in various sizes and shapes to meet your specific needs.

Yes, MgO crucibles are often suitable for use in vacuum or inert gas environments. However, it's essential to check the manufacturer's specifications and recommendations to ensure compatibility with specific conditions.

Store magnesium oxide crucibles in a clean and dry environment to prevent contamination.

Let the crucible cool completely before cleaning. Use a soft brush to gently remove any residual material. Avoid using abrasive materials or harsh chemicals that may damage the crucible.

Just send us inquiries, our team will prepare an official quote for you. If you are satisfied with our products and quotes, you can send us PO or we will send you PI for purchasing.

Bank Wire Transfer: Direct bank transfers are a secure and widely used method. Details for wire transfers will be provided on the invoice.

PayPal: For added flexibility, PayPal payments are often accepted. This option is ideal for those who prefer online payment gateways.

Letter of Credit (L/C): In certain cases, we may accept payment through a letter of credit, offering a secure method for international transactions.

We use UPS or DHL or FedEx express for most of countries. Please let us know if you have their account number. We can ship the items out by using your account number. We use IPS express for Iran, Iraq and UAE. We will by sea or air if the weight or volume is large.

Usually delivery time is around 4-5 weeks. The lead time varies based on quantity and material, ranging from 1 to 4 months.

Request a MgO Crucible Quote for Your Projects Now

Solution about MgO Crucible? Our experts are here to help. Contact us for advice on choosing and using MgO Crucibles.

Get a quote now or let us know what you’re looking for and we will get back to you soon!