Sputtering Targets

Evaporation Materials

Evaporation Sources

High Purity Materials

Thin Film Substrates

Crytstal Materials

+86-731-89578196

+86-731-89578196

[email protected]

[email protected]

Sputtering Targets

Titanium crucibles are specialized containers or vessels made from the metal titanium, known for its lightweight nature, high strength, corrosion resistance, and biocompatibility. Due to its unique properties, a titanium crucible is a reliable choice for applications involving high temperatures, corrosive environments, and various chemical reactions.

AEM Deposition offers various titanium crucibles of exceptionally high purity, and smooth surface, but without cracks, voids, and irregular protrusions, ideal for melting highly corrosive materials as well as crystal growth processes. Choose our top-quality titanium crucibles to ensure a reliable and efficient performance for your projects.

Our titanium crucibles are crafted to various shapes and sizes to meet your needs, including rectangular, cylindrical, squared, and other specially shaped crucibles. The volume range we offer is from 1 to 2000ml, and we use only the best quality titanium for high performance. Our titanium crucibles exhibit excellent corrosion resistance, thus working well in extreme environments.

Purity: 99.95% ~99.99%

Density: 4.543

Melting Point: 1668℃

Boiling Point: 3560℃

| Top Diameter (A) | Height (B) | Thickness (C) | Angle (D) | Volume |

|---|---|---|---|---|

| A=0.846" | B=0.465" | C=0.093" | D=15° | 2 ml |

| A=1.48" | B=0.67" | C=0.125" | D=15° | 15 ml |

| A=1.633" | B=0.94" | C=0.093" | D=15° | 25 ml |

| A=2.03" | B=1.02" | C=0.25" | D=15° | 40 ml |

| A=2.80" | B=1.50" | C=0.125" | D=15° | 100 ml |

The dimensions offered above are just for reference. We can provide a variety of titanium crucibles in different sizes and shapes to meet your specific needs for various applications.

The titanium crucible will be securely packed in a wooden case, cushioned with soft materials, to prevent any movement within the case.

We strive for the selection of high-quality titanium materials to ensure purity, implementing strict quality control and check during the overall manufacturing process, so as to meet your unique standards.

We are dedicated to top-quality titanium crucibles by rigorous inspection at every manufacturing process, ensuring our products consistent with specific industry needs, delivering reliable and high-performance solutions for various applications.

Whether various crucible size, shape, our comprehensive customized solutions ensure titanium crucibles can be tailored to specialized applications, delivering premium performance.

Our experienced team works closely with clients by offering expert assistance and guidance within 24 hours against your problems and needs.

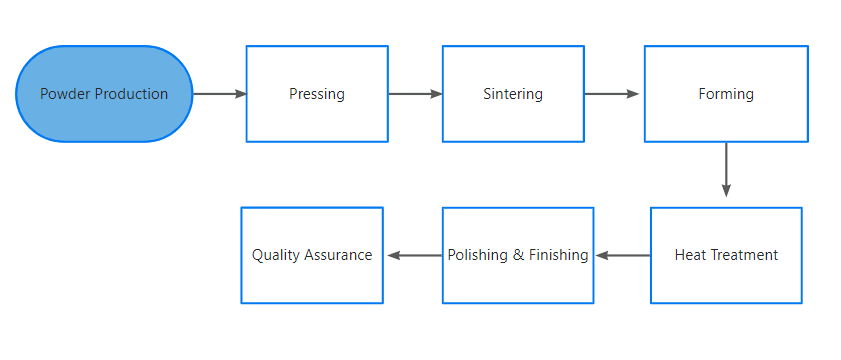

AEM Deposition uses advanced chemical reduction to eliminate contaminants, removing impurities to create ultra-pure, uniform titanium powders.

The tiatanium powder is then molded into the desired shape of the crucible by advanced pressing techniques, striving for high precision.

Our sintering process employs cutting-edge technology, bonding titanium particles to a denser and more cohesive structure. This process enhances the mechanical strength and integrity of the crucible.

The forming method we use is beneficial to the material's density and strength, ensuring our titanium crucibles can meet your unique applications.

Our heat treatment process is crucial to improve properties of the sintered titanium crucible, relieving internal stresses and enhancing the material's overall performance.

Depending on the specific requirements of the application, we offer services including polishing, coating, or other treatments to achieve the desired surface finish.

AEM Deposition implements rigorous quality control measures to ensure the titanium crucible meet the specified standards, always focusing on quality in every step.

Titanium crucibles are used in the metallurgical industry for the melting, casting, and alloying of metals at high temperatures due to their high melting point and corrosion resistance.

Titanium crucibles are commonly used in research and development laboratories where high-temperature processes and corrosion resistance are critical for experimental work.

Titanium crucibles are employed in chemical industries for handling corrosive chemicals and reactions. Their corrosion resistance ensures that they remain stable when exposed to aggressive chemical environments.

Titanium's biocompatibility makes crucibles suitable for the preparation of specialized compounds and substances used in the medical or pharmaceutical industry.

They can withstand extremely high temperatures with a melting point, suitable for applications involving high temperatures, such as in the melting and casting of metals.

Titanium crucibles exhibit excellent thermal conductivity, allowing for efficient heat transfer.

Despite their strength, they are highly malleable, allowing for the fabrication of custom-shaped crucibles to meet specific requirements.

Titanium is a lightweight metal, which makes titanium crucibles easy to handle and maneuver in laboratory settings.

Titanium crucibles are highly resistant to corrosion, ideal for use with a wide range of chemicals and harsh environments.

Titanium is known for its high strength-to-weight ratio, providing durability and structural integrity to the crucibles.

Titanium is biocompatible, making it suitable for use in applications involving biological or medical materials.

Titanium crucibles are durable and have a long lifespan, making them a cost-effective choice for certain applications.

When you're looking to buy a titanium crucible, here are some key points to keep in mind:

Verify the purity level of the titanium material used in the crucible, especially for special uses like in electronics. Check the specifications provided by the manufacturer for details on purity.

Consider the size and capacity requirements for your application. Titanium crucibles are available in various shapes and sizes, and choosing the right dimensions is essential for optimizing performance and efficiency in your processes.

Ensure the crucible material is compatible with the substances it will come into contact with during processing.

Understand the specific requirements of your application. Ensure that the chosen titanium crucible aligns with the intended use.

Check if the supplier offers customization options for titanium crucibles. Depending on your application, you may require specific features or modifications in terms of shape, size, or other characteristics. Customization can ensure that the crucible meets your exact needs.

Check the delivery times and lead times of titanium crucibles, especially if you have time-sensitive projects. Ensure that the supplier can meet your required timelines and has a reliable shipping process.

Temperature Resistance: Titanium crucibles can withstand temperatures up to about 1668℃ , while alumina crucibles can typically handle temperatures up to around 1600℃.

Thermal Conductivity: Both of titanium and alumina have lower thermal conductivity, however, this property of alumina is much lower than titanium.

Density and Weight: Titanium crucibles are lightweight due to the low density, but alumina crucibles are generally denser than titanium crucibles.

Corrosion Resistance: Titanium crucibles are highly corrosion-resistant, while alumina crucibles are not as corrosion-resistant as titanium crucibles in certain aggressive environments.

Fragility: Titanium crucibles are generally more ductile and less prone to breakage compared to alumina crucibles.

Yes, titanium crucibles can be customized to meet specific industrial requirements in terms of size and shape.

Yes, the purity of titanium can affect the pricing of crucibles. Higher-purity titanium may be more expensive. Consider the required level of purity based on your application needs and budget.

Choosing the right titanium crucible depends on your specific application requirements, including size, purity, temperature, and corrosion resistance needs.

Yes, titanium crucibles are often reusable, but their lifespan may depend on factors such as the severity of use, the type of materials melted, and proper maintenance. Regular inspection and adherence to manufacturer recommendations are important for prolonging their use.

Just send us inquiries, our team will prepare an official quote for you. If you are satisfied with our products and quotes, you can send us PO or we will send you PI for purchasing.

Bank Wire Transfer: Direct bank transfers are a secure and widely used method. Details for wire transfers will be provided on the invoice.

PayPal: For added flexibility, PayPal payments are often accepted. This option is ideal for those who prefer online payment gateways.

Letter of Credit (L/C): In certain cases, we may accept payment through a letter of credit, offering a secure method for international transactions.

Our titanium crucibles typically come with certifications that confirm their quality, purity, and compliance with industry standards. Specific certifications can be provided upon request.

We use UPS or DHL or FedEx express for most of countries. Please let us know if you have their account number. We can ship the items out by using your account number. We use IPS express for Iran, Iraq and UAE. We will by sea or air if the weight or volume is large.

Usually delivery time is around 4-5 weeks. The lead time varies based on quantity and material, ranging from 1 to 4 months.