Sputtering Targets

Evaporation Materials

Evaporation Sources

High Purity Materials

Thin Film Substrates

Crytstal Materials

+86-731-89578196

+86-731-89578196

[email protected]

[email protected]

Sputtering Targets

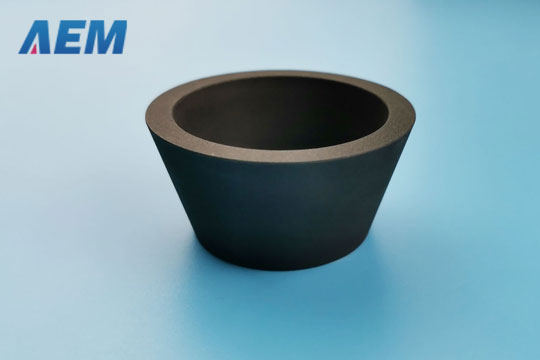

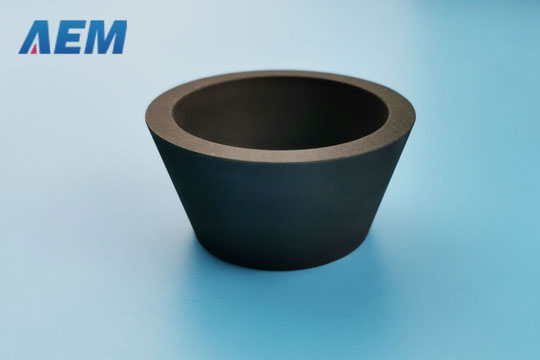

A graphite crucible is a container made of graphite and it is used to melt and hold metals. They can be used at temperatures up to 1600℃ or (3000 °F) and are suitable for refining and melting precious metals and base metals and other products. The graphite crucible is a cost-effective substitute for metal crucibles such as copper, platinum, quartz, or porcelain. It's chemically inert and heat-resistant, performing well in the furnace.

AEM Deposition sources high-purity raw materials, and follows strict manufacturing processes to ensure the highest quality of every graphite crucible featuring excellent thermal conductivity, and high resistance to chemical reactions. Additionally, we can offer graphite crucibles in different shapes and sizes to meet your specific needs, ensuring versatility and flexibility in their usage.

We offer graphite crucibles in various shapes and sizes to meet your needs, including rectangular, cylindrical, squared, and other specially shaped crucibles. The volume range we offer is from 1 to 2000ml, and the maximum working temperature of our graphite crucibles can be up to 1600℃ or 3000 °F.

Purity: 99.99%

Color: Black

Density: 2.3 g/cm3

Melting Point: 3850℃

| Top Diameter (A) | Height (B) | Thickness (C) | Angle (D) | Volume |

|---|---|---|---|---|

| A=0.706" | B=0.465" | C=0.093" | D=15° | 2 ml |

| A=1.48" | B=0.67" | C=0.125" | D=15° | 15 ml |

| A=1.633" | B=0.94" | C=0.093" | D=15° | 25 ml |

| A=2.03" | B=1.02" | C=0.093" | D=15° | 40 ml |

| A=2.7" | B=1.49" | C=0.093" | D=15° | 100 ml |

The dimensions offered above are just for reference. We can provide a variety of graphite crucibles in different sizes and shapes to meet your specific needs for various applications.

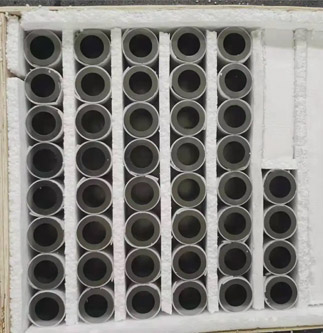

We strive for the highest-quality graphite crucibles, implementing strict quality control and check during the overall manufacturing process, so as to meet your unique standards.

We are dedicated to top-quality graphite crucibles by rigorous inspection at every manufacturing process, ensuring our graphite crucibles consistent with specific industry needs, delivering reliable and high-performance solutions for various applications.

Whether various crucible size, shape, our comprehensive customized solutions ensure graphite crucibles can be tailored to specialized applications, delivering premium performance.

Our experienced team works closely with clients by offering expert assistance and guidance within 24 hours against your problems and needs.

Graphite crucibles play a vital role in high-temperature applications, especially in furnaces and processes involving extreme heat. These crucibles are designed to withstand the intense thermal conditions.

Graphite crucibles are employed in chemical reactions necessitating high temperatures, such as organic synthesis, polymerization, and pyrolysis processes.

Graphite crucibles are used in the production of semiconductors like silicon and germanium. It is used for growing single crystals of these semiconductors at high temperatures.

Graphite crucibles are utilized for melting and casting various metals and alloys such as gold, silver, and copper. They're also employed in the manufacture of steel, iron, aluminum, and other metals that necessitate high-temperature melting.

Graphite crucibles play a key role in jewelry and sculpture production. They enable artists to melt metal and cast it into molds, resulting in unique, one-of-a-kind pieces.

They are used in chemical labs for high-temperature experiments and compound synthesis, providing a controlled environment for reactions, ensuring the purity of the processed substances.

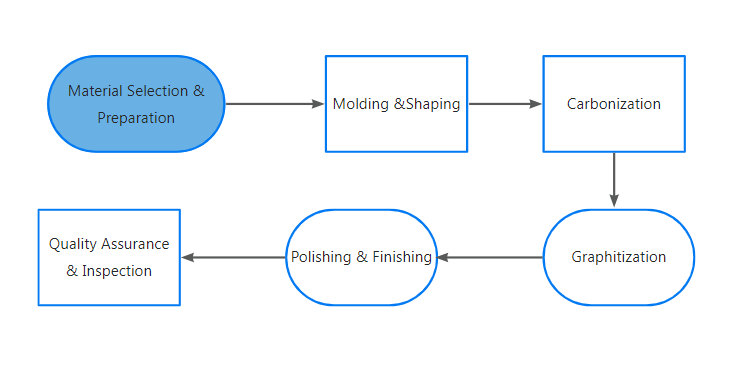

The preparation of raw material of AEM Deposition begins with the selection of premium-quality graphite powder, which is then combined with binders and additives to improve its plasticity and moldability.

We employ isostatic pressing techniques to shape the molten graphite into your desired needs with consistent density and strength across the crucible.

AEM Deposition heats the crucible-like graphite under a specific temperature, usually around 1000°C, in a controlled environment, transforming the molded graphite into a solid carbon structure.

We expose the carbonized crucibles to extremely high temperatures, typically in the range of 2500 to 3000 degrees Celsius, improving the thermal conductivity, strength, and other desirable properties of the graphite material.

Once graphitized, AEM Deposition equips himself with precision mechanical processing, involving machining, polishing, and inspection to eliminate surface flaws, and achieve precise dimensions.

Throughout the manufacturing process, we implement strict quality control measures to ensure the crucibles meet the required standards, including testing for thermal conductivity, density, strength, and resistance to thermal shock. Only crucibles that pass these quality tests are deemed suitable for use.

Graphite crucibles stand out for several desirable properties that make them suitable for high-temperature applications. Here are some key properties of graphite crucibles:

Graphite is an excellent electrical conductor, making graphite crucibles suitable for applications where electrical resistance needs to be minimized.

Graphite crucibles exhibit excellent chemical resistance, ensuring minimal reaction with molten metals and corrosive substances.

They can withstand extreme temperatures, allowing them ideal for applications involving molten metals, alloys, and other high-temperature processes.

Graphite exhibits low thermal expansion, minimizing the risk of thermal shock and cracking during rapid temperature changes.

Graphite has low wettability, meaning molten metals do not readily adhere to its surface. This property facilitates easy removal of the solidified metal from the crucible, simplifying the casting and recycling processes.

Graphite crucibles are known for their strength and durability, enabling multiple uses without compromising performance.

When you're looking to buy a graphite crucible, here are some key points to keep in mind:

Verify the purity level of the graphite material used in the crucible, especially for special uses like in electronics. Check the specifications provided by the manufacturer for details on purity.

Consider the size and capacity requirements for your application. Graphite crucibles are available in various shapes and sizes, and choosing the right dimensions is essential for optimizing performance and efficiency in your processes.

Ensure the crucible material is compatible with the substances it will come into contact with during processing.

Understand the specific requirements of your application. Ensure that the chosen graphite crucible aligns with the intended use.

Check if the supplier offers customization options for customization crucibles. Depending on your application, you may require specific features or modifications in terms of shape, size, or other characteristics. Customization can ensure that the crucible meets your exact needs.

Check the delivery times and lead times of graphite crucibles, especially if you have time-sensitive projects. Ensure that the supplier can meet your required timelines and has a reliable shipping process.

To extend the lifespan and enhance the performance of graphite crucibles, it's essential to handle and maintain them correctly. Adhere to these instructions:

Slowly heat the crucible to the desired temperature to reduce the chance of thermal shock.

Rapid changes in temperature can induce thermal stress, resulting in cracks in the crucible.

After each use, clear the crucible of any residue or impurities to avoid contamination.

To avoid moisture absorption that could weaken the material, keep the crucibles in a dry location.

The maximum working temperature of our graphite crucibles can be up to 1600℃ or 3000 °F.

Yes, we can provide customization in various sizes and shapes to meet your specific needs.

Yes, we do offer samples before placing a large order. This allows you to assess the quality and suitability of our graphite crucibles for your specific needs.

Graphite crucibles are usually shipped with protective packaging to prevent damages during the shipment. They should be stored in a dry environment to avoid moisture absorption.

Bank Wire Transfer: Direct bank transfers are a secure and widely used method. Details for wire transfers will be provided on the invoice.

PayPal: For added flexibility, PayPal payments are often accepted. This option is ideal for those who prefer online payment gateways.

Letter of Credit (L/C): In certain cases, we may accept payment through a letter of credit, offering a secure method for international transactions.

We use UPS or DHL or FedEx express for most of countries. Please let us know if you have their account number. We can ship the items out by using your account number. We use IPS express for Iran, Iraq and UAE. We will by sea or air if the weight or volume is large.

Usually delivery time is around 4-5 weeks. The lead time varies based on quantity and material, ranging from 1 to 4 months.