Evaporation Boats

|

|

|

The tungsten, molybdenum, tantalum evaporation boats have a high melting point, good electrical conductivity and low vapor pressures. These charcterissitics make them as the excellent evaporation source for materials evaproation.

Due to the low vapor pressure of our boats, there is no tungsten, tantalum and molybdenum particles will enter the vapor or contaminated the evaporation materials during application. AEM provides high qulaity evaporation boats with customized sizes.

To get the quotation for boats or related information, you may click the “inquiry” button. Then fill in the inquiry form or reach us via email at [email protected], our sales department will reply to you as soon as possible.

Evaporation Boats Specifications

| Materials |

Molybdenum Evaporation Boats |

Tungsten Evaporation Boats |

Tantalum Evaporation Boats |

| Symbol | Mo | W | Ta |

| Purity | 99.95% | 99.95% | 99.95% |

| Theoretical Density (g/cc) | 10.2 | 19.25 | 16.6 |

| Melting Point (°C) | 2617 | 3,410 | 3,017 |

| Thermal Conductivity | 139 W/m.K | 174 W/m.K | 57 W/m.K |

Shapes of Evaporation Boats

1. Trough Boats

2. Dimple Boats

3. Notched Boats

4. Canoe Boats

5. Holed/ Covered Boats

6. Slab/ Flat/ Dish Boats

7. Well Boats

8. Tube Heater/ Crucible Heater Boats

9. Elongated Dimple Boats

Dimensions of Evaporation Boats

| Type |

Length (mm) |

Width (mm) |

Length or Diameter of the Recess (mm) |

Depth of the Recess (mm) |

Thickness (mm) |

Volume (cc) |

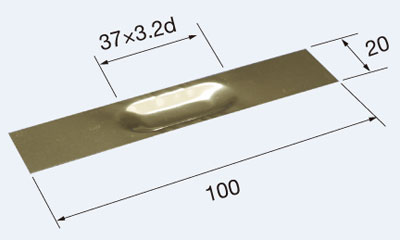

| AEMEB-1 | 100 mm | 20 mm | 37 mm | 3.2 mm | 0.1 mm, 0.2 mm , 0.3 mm | 0.62 cc |

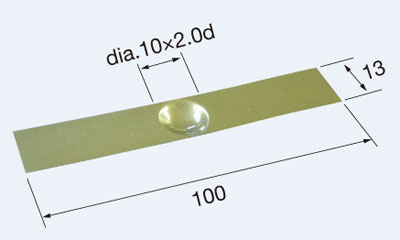

| AEMEB-2 | 100 mm | 13 mm | 10 mm | 2.0 mm | 0.1 mm, 0.2 mm , 0.3 mm | 0.07 cc |

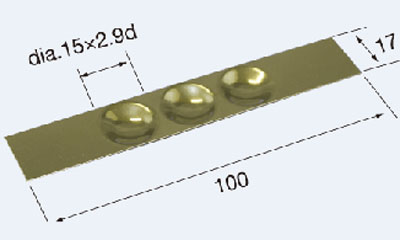

| AEMEB-3 | 100 mm | 17 mm | 15 mm | 2.9 mm | 0.1 mm, 0.2 mm , 0.3 mm | 0.23 cc |

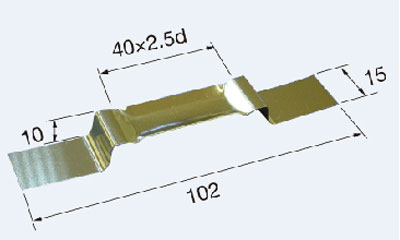

| AEMEB-4 | 102 mm | 15 mm | 40 mm | 2.5 mm | 0.1 mm, 0.2 mm , 0.3 mm | 0.83 cc |

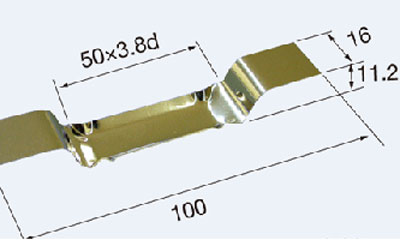

| AEMEB-5 | 100 mm | 16 mm | 50 mm | 3.8 mm | 0.1 mm, 0.2 mm , 0.3 mm | 2.04 cc |

| AEMEB-6 | 100 mm | 13 mm | 18 mm | 2.0 mm | 0.1 mm, 0.2 mm , 0.3 mm | 11.2 cc |

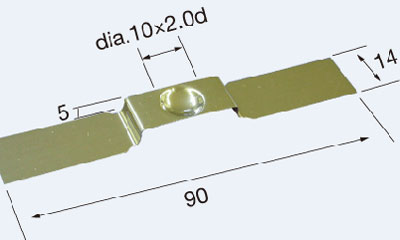

| AEMEB-7 | 90 mm | 14 mm | 10 mm | 2.0 mm | 0.1 mm, 0.2 mm , 0.3 mm | 0.07 cc |

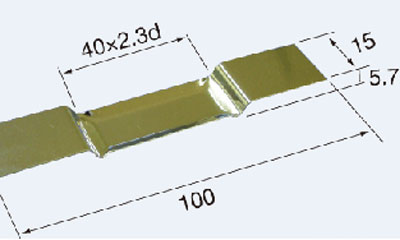

| AEMEB-8 | 100 mm | 15 mm | 40 mm | 2.3 mm | 0.1 mm, 0.2 mm , 0.3 mm | 0.74 cc |

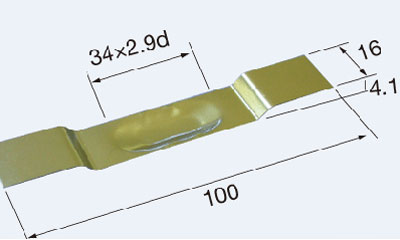

| AEMEB-9 | 100 mm | 16 mm | 34 mm | 2.9 mm | 0.1 mm, 0.2 mm , 0.3 mm | 0.61 cc |

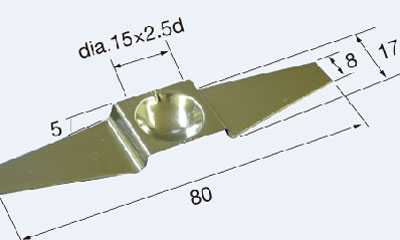

| AEMEB-10 | 100 mm | 17 mm | 15 mm | 2.5 mm | 0.1 mm, 0.2 mm , 0.3 mm | 0.2 cc |

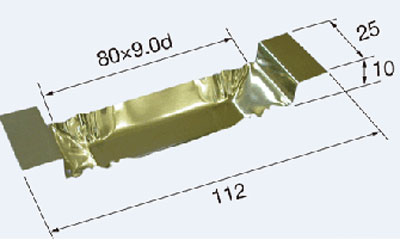

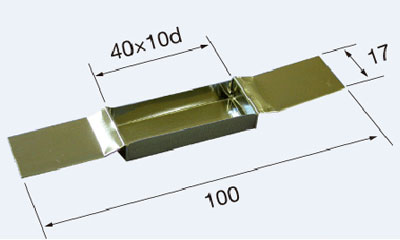

| AEMEB-11 | 100 mm | 17 mm | 40 mm | 10 mm | 0.1 mm, 0.2 mm , 0.3 mm | 5.79 cc |

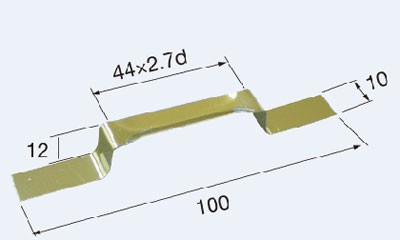

| AEMEB-12 | 100 mm | 10 mm | 44 mm | 2.7 mm | 0.1 mm, 0.2 mm , 0.3 mm | 0.44 cc |

| The customized size can be porvided accroding to customer's drawings. | ||||||

Drawings of Evaporation Boats

|

|

|

|

|||

| AEMEB-1 | AEMEB-2 | AEMEB-3 | AEMEB-4 | |||

|

|

|

|

|||

| AEMEB-5 | AEMEB-6 | AEMEB-7 | AEMEB-8 | |||

|

|

|

|

|||

| AEMEB-9 | AEMEB-10 | AEMEB-11 | AEMEB-12 |

Applications of Evaporation Boats

1. As a container, evaporation boats are used for the analysis of materials and products;

2. Designed for burning solid materials.

Precautions to Use of Evaporation Boats

1. Put the items that need to be analyzed then heat them into the crucible or sagger;

2. The heating temperature increase and decrease are according to the characteristics of equipment and products;

3. Too quick heating or cooling will lead to cracking of the evaporation boat. The best way is slowing down the heating process, which can prolong the life of combustion boats.