+86-731-89578196

+86-731-89578196

[email protected]

[email protected]

- Home

- Our Company

-

Products

Sputtering Targets

- Industries

- Blog

- FAQ

- Contact Us

What is the Thermal Evaporation?

One of the common methods of Physical Vapor Deposition (PVD) is Thermal Evaporation. This is a form of Thin-film Deposition, which is a vacuum technology for applying coatings of pure materials to the surface of various objects. The coatings, also called films, are usually in the thickness range of angstroms to microns and can be a single material or multiple materials in a layered structure.

Two Primary Means of Heating the Source Material

One method, often referred to as Filament Evaporation, is a simple electrical resistive heat element or filament. There are numerous different physical configurations of these resistive evaporation filaments, including many known as "boats" - nearly thin sheet metal pieces of suitable high-temperature metals (such as tungsten) with formed indentations or troughs into which the material is placed. The filament source offers low voltage safety, although a very high current is required, usually several hundred amps.

The other common heat source is an Electron Beam or E-Beam, which is generally known as E-Beam Evaporation. This is certainly a more "high tech" approach to heating a material up and involves some dangerous high voltage (usually 10,000 volts), so E-Beam systems always include extra safety features. The source itself is an E-Beam "gun". A small and very hot filament boils off electrons, which are then accelerated by the high voltage, forming an electron beam with considerable energy.

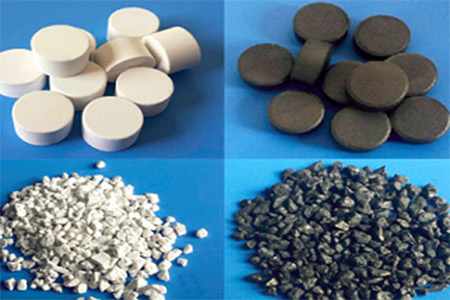

AEM Deposition is an international evaporation materials manufacturer. We have over 10 years to produce and sell evaporation materials, including Pure Metal Evaporation Materials, Alloy Evaporation materials, Oxide Evaporation Materials, and Compound Evaporation Materials. All materials are provided with various shapes, pieces, pellets, powder, rods, wires, or others. If you are interested in AEM Deposition's evaporation materials, you can click the link to get more details.