Sputtering Targets

Evaporation Materials

Evaporation Sources

High Purity Materials

Thin Film Substrates

Crytstal Materials

+86-731-89578196

+86-731-89578196

[email protected]

[email protected]

Sputtering Targets

Copper (Cu), a reddish-orange metal valued for its exceptional conductivity of heat and electricity, is a vital building block of our modern world. Its softness makes it easy to work with, and its durability makes it a reliable choice for various applications.

At AEM DEPOSITION, we specialize in high-purity copper evaporation materials to meet the demanding needs of manufacturers. We offer copper in convenient pellet and granule forms, with customization options for specific shapes.

Our copper boasts an impressive purity of up to 99.999%, guaranteeing exceptional results and superior film quality during the evaporation process. We are dedicated to rigorous quality control, ensuring every batch meets the highest standards for consistent performance and reliability.

Let AEM DEPOSITION be your trusted source for high-quality copper evaporation materials. Contact us today for a personalized quote.

| Material Type | Copper |

|---|---|

| Symbol | Cu |

| Atomic Weight | 63.546 |

| Atomic Number | 29 |

| Color/Appearance | Copper, Metallic |

| Thermal Conductivity | 400 W/m.K |

| Melting Point (°C) | 1,083 |

| Coefficient of Thermal Expansion | 16.5 x 10-6/K |

| Theoretical Density (g/cc) | 8.92 |

|---|---|

| Z Ratio | 0.437 |

| E-Beam | Excellent |

| Thermal Evaporation Techniques |

Boat: Mo, W

Coil: W

Basket: W

Crucible: Al2O3, Mo, Ta |

| E-Beam Crucible Liner Material | Graphite, Molybdenum |

| Temp. (°C) for Given Vap. Press. (Torr) |

10-8: 727

10-6: 857

10-4: 1,017 |

| Comments | Adhesion poor. Use interlayer (Cr). Evaporates using any source material. |

Our copper evaporation materials, with up to 99.999% purity, produce high-quality thin films with fewer impurities. This makes them perfect for use in electronics, solar panels, and display technologies.

Consistency is key in deposition processes. Our copper evaporation materials are carefully processed and tested to ensure uniform composition and particle size, delivering reliable and repeatable film quality for all your deposition needs.

We offer copper evaporation materials in pellet, granule and powder forms, with customization options to meet your specific application requirements. Whether you need specific dimensions, shapes, or packaging, we can tailor our products to suit your needs.

Whether for research or large-scale production, we offer high-quality copper evaporation materials at competitive prices. You can count on us for both cost-effectiveness and premium performance, no matter the size of your order.

AEM DEPOSITION takes pride in providing fast and reliable delivery, no matter where you are located. With a strong supply chain, we ensure that you receive your evaporation materials on time, keeping your projects on schedule.

Copper is a popular choice for evaporation processes due to its many useful properties. Here's why copper pellets are widely used:

When evaporated, copper sticks well to many surfaces, creating durable and long-lasting coatings. This is especially important for electronics and solar panels that need reliable performance.

Copper is one of the best conductors of electricity. This makes it perfect for creating thin conductive layers in devices like circuit boards and sensors.

Copper pellets melt and evaporate evenly, ensuring that the coating is applied smoothly. This consistency is vital for applications that need uniform film thickness, like precision optics or electronics.

Copper naturally forms a protective oxide layer, helping resist corrosion. This makes it useful for coatings that need to last in slightly corrosive environments, like moisture or air exposure.

Copper pellets can be used with different evaporation methods, such as thermal or electron beam evaporation, offering flexibility across various industrial processes.

Copper expands very little when heated, reducing the risk of cracks or defects during evaporation. This ensures a smoother and more reliable process.

Copper evaporation materials, such as copper pellets, are widely used in various industries due to their reliable performance and versatile properties. Here are some of the key applications:

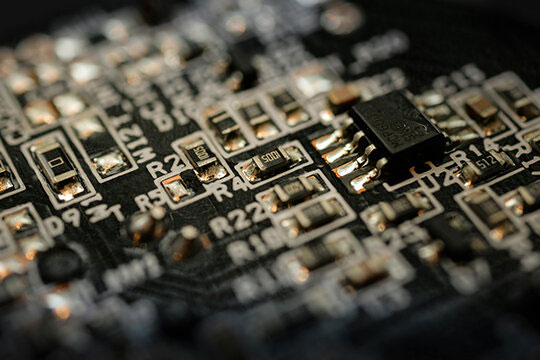

Copper is widely used in semiconductor manufacturing for creating thin conductive layers in microchips and circuit boards. Its excellent electrical conductivity is crucial for ensuring reliable performance in modern electronics.

Copper pellets are used to deposit thin films on lenses, mirrors, and other optical components. These coatings improve light transmission and reflection, making copper essential in the production of high-performance optical devices.

In the renewable energy sector, copper is used to coat photovoltaic cells in solar panels. These copper layers enhance the efficiency of energy conversion, helping increase the overall performance of solar cells.

Copper is used in the manufacturing of hard drives and other data storage systems. Thin copper films provide the conductive pathways that allow reliable data storage and retrieval.

Copper evaporation materials are critical in the production of thin-film transistors (TFTs) for flat-panel displays like LCDs and OLEDs. Copper's conductivity ensures efficient electrical flow, improving screen clarity and performance.

Copper thin films are essential in microelectronics, forming miniature wiring for devices like smartphones, tablets, and wearable tech. Its ability to conduct electricity efficiently in small spaces makes copper a top choice for these applications.

When choosing copper evaporation materials, buyers should consider factors such as purity level, material form (pellets, granules, or powder), required deposition rate, and compatibility with the evaporation system. High-purity copper (99.99% or higher) is recommended for applications requiring minimal contamination, such as semiconductors or optical coatings.

The purity of copper evaporation materials directly affects the quality of the deposited thin films. Higher purity materials produce films with fewer defects, improved electrical conductivity, and better adhesion. For precision applications, we recommend 99.999% pure copper to minimize impurities.

Copper evaporation materials are commonly used in physical vapor deposition (PVD) techniques such as thermal evaporation and electron-beam (e-beam) evaporation. The choice of technique depends on the desired film thickness, uniformity, and the specific equipment available.

In thermal evaporation, copper is heated until it vaporizes, while in electron-beam (e-beam) evaporation, a focused electron beam heats the copper. E-beam evaporation offers more precise control over the process, making it ideal for high-purity applications. Thermal evaporation is more cost-effective for less demanding applications.

To ensure consistent deposition rates, it is critical to maintain stable evaporation conditions, including temperature control, vacuum pressure, and material feed. Using high-purity copper materials also minimizes variability due to contaminants.

Copper's high electrical conductivity and resistance to corrosion make it a popular choice in the electronics industry for fabricating conductive films in devices such as printed circuit boards (PCBs), displays, and sensors. Evaporated copper layers ensure efficient electrical performance and durability in harsh environments.

Yes, copper evaporation materials are widely used in decorative coatings to produce aesthetically appealing finishes on products such as jewelry, watches, and consumer electronics. Copper’s warm metallic appearance and ease of deposition make it a popular choice for achieving premium finishes.

Yes, copper evaporation materials are sometimes used in medical device manufacturing, particularly for creating biocompatible, antimicrobial coatings. Copper's natural antimicrobial properties make it valuable for medical instruments and surfaces, helping reduce bacterial contamination.

| Pure Metal Sputtering Targets | |

| Alloy Sputtering Targets | |

| Ceramic Sputtering Targets | |

| Evaporation Materials | |

| Crucibles | |

| Metal Powders |