Sputtering Targets

Evaporation Materials

Evaporation Sources

High Purity Materials

Thin Film Substrates

Crytstal Materials

+86-731-89578196

+86-731-89578196

[email protected]

[email protected]

Sputtering Targets

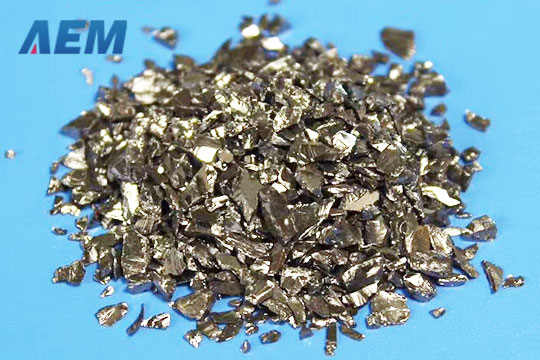

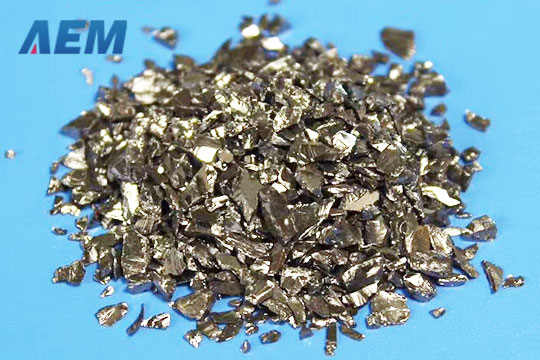

Silicon, a versatile metal-like element with a bluish color, is essential to modern technology. Its ability to withstand high temperatures and resist evaporation makes it perfect for many uses, especially in electronics and computers.

At AEM DEPOSITION, we specialize in providing high-purity silicon evaporation materials tailored to meet the exacting demands of manufacturers. Our silicon is available in various forms, including pellets and granules, and can be customized to your specific requirements.

Whether you're a seasoned manufacturer or just starting out, AEM DEPOSITION is your trusted supplier of high-quality silicon evaporation materials. Contact us today to discuss your specific requirements and receive a personalized quote.

Let AEM DEPOSITION be your trusted source for high-quality copper evaporation materials. Contact us today for a personalized quote.

| Material Type | Silicon (P-type) |

|---|---|

| Symbol | Si (P-type) |

| Atomic Weight | 28.0855 |

| Atomic Number | 14 |

| Color/Appearance | Dark Gray with a Bluish Tinge, Semi-Metallic |

| Thermal Conductivity | 150 W/m.K |

| Melting Point (°C) | 1,410 |

| Bulk Resistivity | 0.005-0.020 OHM-CM |

| Coefficient of Thermal Expansion | 2.6 x 10-6/K |

| Theoretical Density (g/cc) | 2.32 |

| Dopant | Boron |

|---|---|

| Z Ratio | 0.712 |

| E-Beam | Fair |

| E-Beam Crucible Liner Material | Fabmate®, Tantalum |

| Temp. (°C) for Given Vap. Press. (Torr) |

10-8: 992 10-6: 1,147 10-4: 1,337 |

Our silicon evaporation materials, with up to 99.999% purity, produce high-quality thin films with fewer impurities. This makes them perfect for use in electronics, solar panels, and display technologies.

Consistency is key in deposition processes. Our silicon evaporation materials are carefully processed and tested to ensure uniform composition and particle size, delivering reliable and repeatable film quality for all your deposition needs.

We offer silicon evaporation materials in pellet, granule and powder forms, with customization options to meet your specific application requirements. Whether you need specific dimensions, shapes, or packaging, we can tailor our products to suit your needs.

Whether for research or large-scale production, we offer high-quality silicon evaporation materials at competitive prices. You can count on us for both cost-effectiveness and premium performance, no matter the size of your order.

AEM DEPOSITION takes pride in providing fast and reliable delivery, no matter where you are located. With a strong supply chain, we ensure that you receive your evaporation materials on time, keeping your projects on schedule.

Silicon is a popular choice for evaporation processes due to its many useful properties. Here's why copper pellets are widely used:

Remarkable thermal stability allows silicon to perform consistently even under extreme conditions, making it suitable for high-temperature processes.

Silicon's low vapor pressure minimizes material loss during evaporation, maximizing yields and efficiency in manufacturing processes.

Consistent particle size ensures uniform evaporation rates, which is essential for achieving high-quality thin films in coatings and electronics.

Decent electrical conductivity makes silicon pellets effective for various electronic applications, including solar cells and semiconductor devices.

Excellent chemical stability reduces the risk of unwanted reactions during evaporation, contributing to the longevity and reliability of final products.

Silicon's relatively low melting point allows for easier handling and processing, enabling efficient evaporation at lower temperatures and reducing energy consumption.

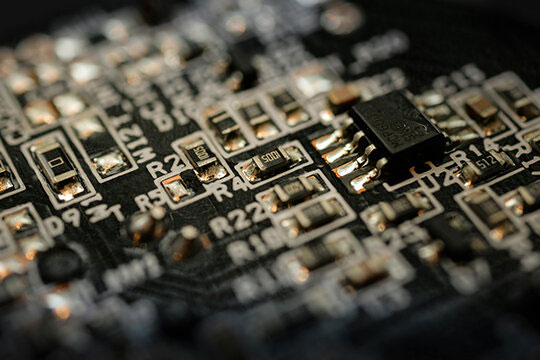

Silicon is fundamental in the production of semiconductor devices. It serves as a substrate for integrated circuits, ensuring efficient electron mobility and performance.

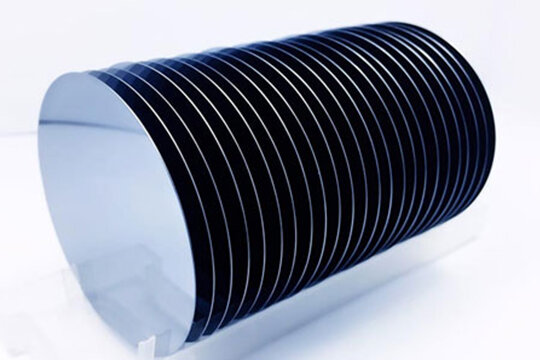

Silicon pellets are prominently used in the production of silicon wafers, serving as the foundation for various semiconductor applications, including solar cells and microelectronics.

Silicon evaporation materials are applied in optical coatings for lenses and mirrors, enhancing their reflectivity and durability in various optical devices.

Silicon pellets serve as sputtering targets in thin-film deposition processes, critical for producing coatings in electronics and other industries.

Yes, we offer customization solutions, including tailored pellet sizes, shapes, and purity levels. Simply provide your specifications, and we will produce silicon pellets to match your project requirements.

For evaporation processes, particularly in high-tech industries like semiconductors and optics, silicon pellets with a purity of 99.999% (5N) or higher are recommended. Higher purity ensures better film quality and reduces the risk of contamination during the coating or thin-film deposition process.

Silicon pellets are used for evaporation in several industries, such as semiconductors, optics, and coatings. In the semiconductor industry, they help create thin layers on microchips and electronic devices. The optics industry uses them to make anti-reflective coatings for lenses and other optical products. In coatings, they are applied to protect surfaces, especially in fields like aerospace and automotive manufacturing.

The evaporation rate of silicon pellets is influenced by factors such as the vacuum pressure in the evaporation chamber, the temperature of the crucible, and the purity of the pellets. Achieving the right balance between these factors ensures efficient evaporation and high-quality thin films.

Silicon pellets are typically evaporated using electron beam (e-beam) evaporators or thermal evaporation systems. These systems heat the pellets in a vacuum chamber until they vaporize, allowing the silicon to form thin films on the substrate.

The size of the silicon pellets can affect both the rate and uniformity of evaporation. Smaller pellets tend to evaporate faster and more evenly, while larger pellets may require more time to heat and evaporate fully. Consistent pellet size is crucial for stable and predictable evaporation results.

Silicon has a high melting point of around 1,414°C (2,577°F). To achieve effective evaporation, the temperature of the silicon pellets must exceed this point. In electron beam evaporation, temperatures of 1,600°C to 1,800°C are typically used to vaporize silicon for thin-film deposition.

Some common challenges include keeping a steady evaporation rate, avoiding contamination, and ensuring the coating spreads evenly across the surface. To solve these problems, it's important to properly set up your equipment, use high-purity silicon pellets, and maintain good vacuum conditions. This helps create smooth and reliable coatings every time.