+86-731-89578196

+86-731-89578196

[email protected]

[email protected]

- Home

- Our Company

-

Products

Sputtering Targets

- Industries

- Blog

- FAQ

- Contact Us

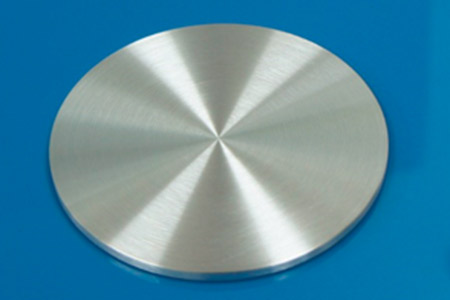

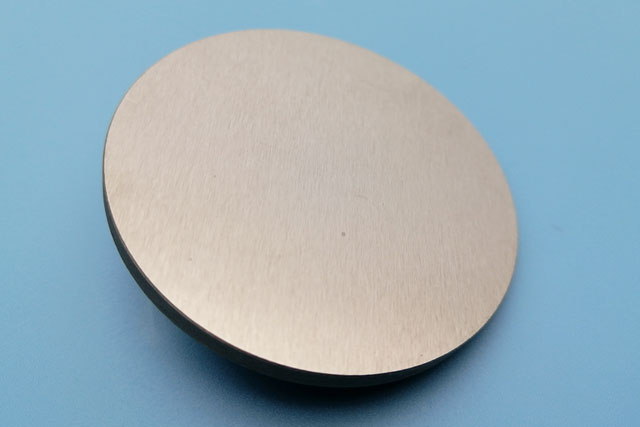

Manufacturing of Sputtering Targets

Metal sputtering targets are typically made from cast ingot. The metal or alloy is melted and solidified to ensure full density with a minimum amount of voids. The casting process can be performed in a vacuum or inert atmosphere to reduce the presence of oxides. The majority of metals can form oxides that have much higher electrical resistance. The presence of these oxides can create non-uniform sputtering since there is a significant difference between the metal and oxide electrical properties. Metallic targets can be shaped to the final target dimensions through thermomechanical processing (e.g., forging, rolling, and heat treatment).

Sintering powders typically make ceramic sputtering targets and semiconductor targets due to the difficult nature of casting these materials into the necessary target dimensions. Oxides targets, sulfides targets, selenides targets, and tellurides targets are brittle and feature-poor electrical conductivity. These materials can be crushed into powders and then sintered into high-density targets. While oxides such as Al2O3 and ZnO have been studied for many years, new applications have sparked the development of various sulfides, selenides, and tellurides.

These compounds are typically reacted using high-purity starting materials. Most reactions between metals and O, S, Se, and Te are violent and exothermic. In addition, compound formation is generally done in a vacuum to reduce oxides' presence for non-oxide compounds. These reactions can be dangerous since S, Se, and Te vapors can form toxic gases. The production staff's safety comes first, with the secondary goal being to maintain the compound composition as close to the ordered ratio and desired purity level as possible. Typical purity levels of 99.95-99.999% purity can be achieved using this process.

The materials are sized down into fine powders with a key emphasis on avoiding contamination. The powders are then loaded into a graphite mold and introduced into a vacuum hot press. The vacuum hot press subjects the powders to high-temperature and high pressure while in a vacuum environment. The vacuum ensures a limited opportunity for oxidation while the temperature/pressure allows the powders to sinter into a high-density press. Due to the stresses induced during pressing, careful monitoring of the thermal profile is necessary to reduce the likelihood of cracking in the target material.

The powder is sintered into a near-net shape and then ground/machined into the desired dimensions. The target must then be attached to a copper or molybdenum backing plate to be installed in the sputtering system. Metallic targets such as aluminum alloys, titanium, or copper could be machined into the appropriate shape for direct install into the sputtering system. However, ceramic and semiconductor targets require bonding to a copper backing plate since the mounting screws and fixtures could easily create cracks in the brittle target material. Since the materials are not thermally and electrically conductive, care must be taken in the bonding process.