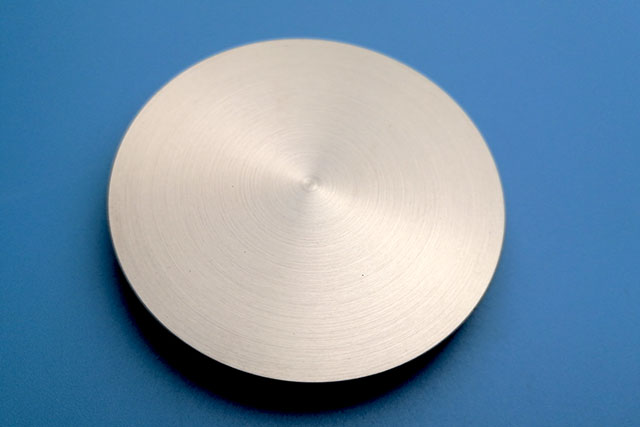

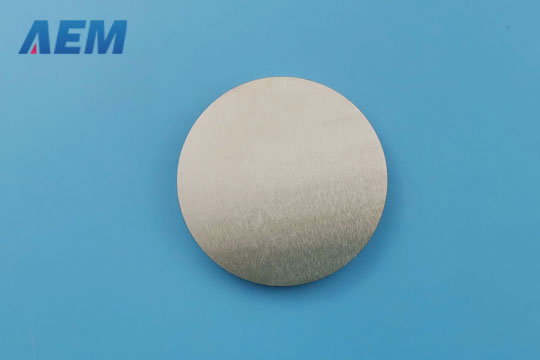

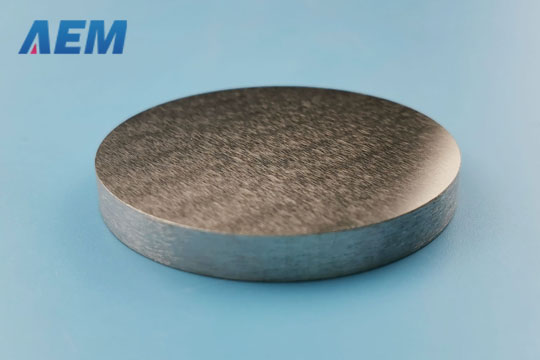

Nickel Titanium Sputtering Targets (Ni/Ti)

| Material Type | Nickel Titanium |

| Symbol | Ni/Ti |

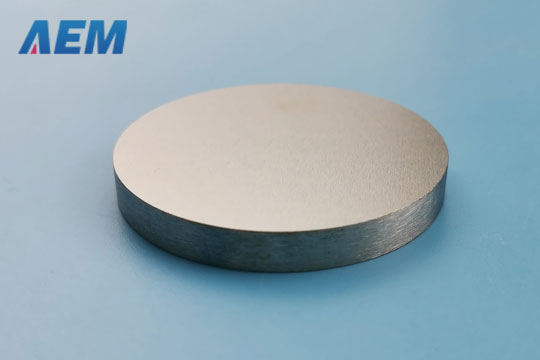

| Color/Appearance | bright silvery |

| Thermal Conductivity | 0.18 W/cm·K |

| Melting Point (°C) | 1310 °C |

| Coefficient of Thermal Expansion | 11×10−6/°C |

| Density | 6.45 g/cm3 |

| Sputter | DC |

| Type of Bond | Indium, Elastomer |

Nickel Titanium Sputtering Targets

Nickel Titanium metal alloy has some unique properties. This alloy exhibits the super-elasticity or pseudo-elasticity and shape memory properties. It means this unique metal can remember its original shape and shows excellent elasticity under stress. The shape memory and super-elasticity properties are the unique properties of this alloy. The shape memory property allows this metal to “remember” its original shape and retain it when heated above its transformation-temperature. It happens due to the different crystal structures of nickel and titanium. This pseudo-elastic metal also shows incredible elasticity, which is approximately 10 to 30 times more than ordinary metal.

Nickel Titanium Sputtering Targets Information

Nickel Titanium Sputtering Targets (Ni/Ti)

Purity: 99.9%;

Circular: Diameter <= 14 inch, Thickness >= 1mm;

Block: Length <= 32 inch, Width <= 12 inch, Thickness >= 1mm.

More Information on Nickel Titanium Sputtering Targets

Applications• Semiconductor• Chemical Vapor Deposition (CVD) • Physical Vapor Deposition (PVD) |

Features• Competitive pricing• High purity • Grain refined, Engineered microstructure • Semiconductor grade |

Manufacturing Process• RefiningThree-layer electrolytic process • Melting and casting Electrical resistance furnace - Semi-continuous casting • Grain refinement Thermomechanical treatment • Cleaning and final packaging - Cleaned for use in vacuum Protection from environmental contaminants Protection during shipment |

Options• 99.9% minimum purity• Smaller sizes also available for R&D applications • Sputtering target bonding service |

Related Products of Nickel Titanium Sputtering Targets

Click to download datasheet about Nickel Titanium Sputtering Targets (Ni/Ti)

Click to download datasheet about Nickel Titanium Sputtering Targets (Ni/Ti)

Unable to find the required data sheet? Click here to send an email and get it.

Unable to find the required data sheet? Click here to send an email and get it.

Click here to get answers to Frequently Asked Questions (FAQ).

Click here to get answers to Frequently Asked Questions (FAQ).