List of Sputtering Targets for Glass Coating

Date: 2021-09-15

Abstract: Correspondingly, the demand of target materials for glass coating is increasing rapidly. The sputtering target materials for glass coating mainly include: silver sputtering target, chromium sputtering target, titanium sputtering target, nickel chromium sputtering target, zinc tin sputtering target, silicon aluminum sputtering target, titanium oxide sputtering target, etc. The details as follows:

List of Sputtering Targets for Coating of Tools and Moulds

Date: 2022-09-15

Abstract: The main types of sputtering targets for tool mould coating are titanium aluminum sputtering target, chromium aluminum sputtering target, chromium sputtering target, titanium sputtering target, etc. The details are as follows:

List of Sputtering Targets for Decorative Coating

Date: 2021-09-15

Abstract: The main types of target materials for decorative coating are: chromium sputtering target, titanium sputtering target, zirconium sputtering target, nickel sputtering target, tungsten sputtering target, titanium aluminum sputtering target, etc. The details are as follows:

Preparation of ITO Sputtering Target by Slurry Casting Forming Atmosphere Sintering

Date: 2021-09-15

Abstract: ITO sputtering target, namely indium tin oxide target, is coated with a transparent and conductive ITO film, on glass substrate or organic film by magnetron sputtering. ITO sputtering target can be prepared by many methods. One of them is the law of sintering in powder casting forming atmosphere.

Preparation of ITO Sputtering Target by Spark Plasma Sintering

Date: 2021-09-15

Abstract: ITO sputtering target has high transmittance and low resistivity. High quality ITO films need ITO sputtering target with high density, purity and uniformity. At present, the preparation methods of ITO sputtering target mainly include hot pressing, cold isostatic pressing sintering and hot isostatic pressing. Today, I would like to introduce the spark plasma sintering method.

The Process of ITO Sputtering Target Prepared by Sintering at Atmospheric Pressure

Date: 2021-09-15

Abstract: The normal pressure sintering method is to prepare high-density target blank by means of pre pressing (or slurry casting). The target blank is sintered in a certain atmosphere and temperature. Through the control of sintering temperature and sintering atmosphere, the growth of target blank grain is effectively controlled to achieve high densification of target and uniformity of grain distribution.

Preparation of ITO Sputtering Target by Vacuum Hot Pressing

Date: 2021-09-15

Abstract: The vacuum hot pressing method refers to the molding or isostatic pressing and both forming methods. It uses heat and mechanical energy to densify the target. Because the heating process and pressure process are carried out at the same time, it is helpful for the mass transfer process of powder particles such as diffusion contact and flow in the sintering process. The vacuum hot pressing method has the advantages of shortening the sintering period, reducing the sintering temperature and effectively restraining the grain size of the target material, which can greatly improve the density of the target material.

Preparation of ITO Sputtering Target: Hot Isostatic Pressure Method

Date: 2021-09-15

Abstract: At present, the preparation methods of ITO sputtering target mainly include hot pressing, cold isostatic pressing sintering and hot isostatic pressing. The ITO target prepared by hot isostatic pressing has the highest quality, and its relative density can reach more than 99%. However, it needs expensive equipment, high preparation cost and long cycle. So, what is the hot isostatic pressure method?

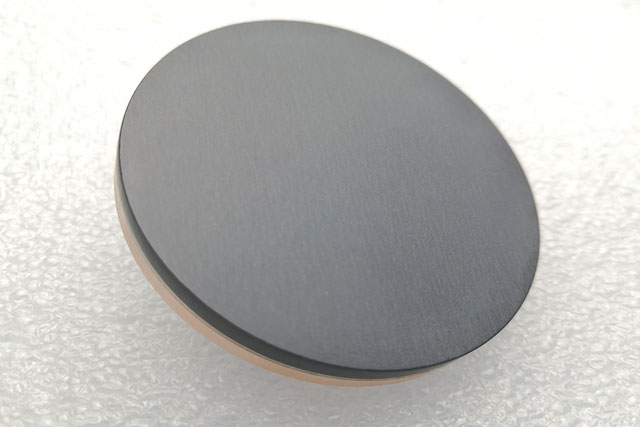

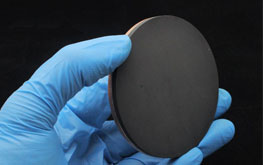

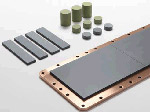

Common Sputtering Back Plate Materials and Instructions for Reuse

Date: 2021-09-16

Abstract: Sputtering targets are divided into panel and back plate. Depending on the material, the sputtering target back plate is also different. At present, the common sputtering target back plate materials are mainly oxygen free copper, molybdenum, stainless steel tubes, indium and other back plate materials. The details are as follows:

Pre Sputtering Time, Power and Water Temperature Control of Sputtering Target

Date: 2021-09-16

Abstract: So what should we pay attention to in the pre sputtering process? In fact, in the pre sputtering process, we only need to control these three points: time, power and water temperature.

What are the Preparations for Sputtering Target Before Use?

Date: 2021-09-16

Abstract: Magnetron sputtering is a new type of physical vapor deposition. The electron gun system is used to shoot and focus the electrons on the material to be plated, making the sputtering atoms follow the principle of momentum conversion and fly away from the material with high kinetic energy to the substrate to form a film. This kind of material is called sputtering target. Today, I'd like to talk with you about some preparations before sputtering.

Copper Pellet Evaporation Material Video

Date: 2021-09-15

Abstract: Copper Pellet Evaporation Material.Brand: AEM Deposition Purity: 99.999%.Diameter: 3 mm.Length: 3 mm.Application: Conductor of heat and electricity;Building material;Strain gauges;Thermocouples for temperature measurement.