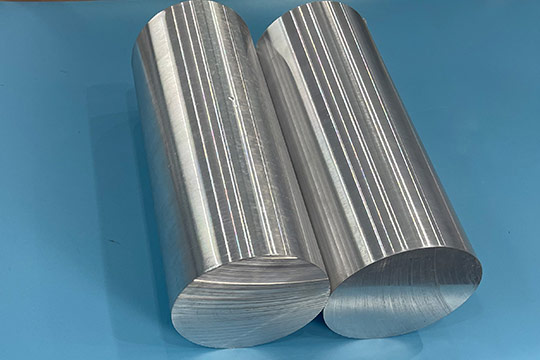

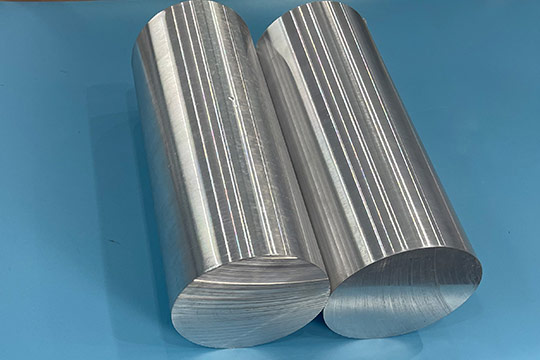

High Purity Aluminum Ingot

Aluminum Ingot Supplier

AEM Deposition is a trusted aluminum ingot supplier offering high-quality aluminum ingots for many industrial applications. Our aluminum ingots are essential raw materials used to produce high-quality finished products.

Our ingots have a very high purity level of up to 99.9999%, meeting even the strictest requirements. Industries including automotive, aerospace, electronics, and construction rely on our aluminum ingots for their excellent quality and consistency.

At AEM Deposition, we provide fast delivery, competitive pricing, and friendly customer support. Using advanced manufacturing methods and strict quality control, we ensure every shipment meets your expectations. Contact us today to discuss your needs or get a quote!

Aluminum Ingot Specifications

Aluminum Ingot Information

| Atomic Symbol | Al |

|---|---|

| Purity | 99.99% - 99.9999% |

| Form | Ingot |

| Density | 2700 kg/m3 |

| Melting Point | 660.37 °C |

| Boiling Point | 2467 °C |

|---|---|

| EINECS No. | 231-072-3 |

| Thermal Conductivity | 2.37 W/cm/ K @ 298.2 K |

| Coefficient of thermal expansion: | (25 °C) 23.1 µm·m-1·K-1 |

Why Choose AEM as Your Aluminum Ingots Supplier?

Outstanding Purity (99.9999%)

Ultra-low impurity levels (≤1 ppm total), ideal for electronics, semiconductor fabrication, aerospace components, and advanced automotive applications.

Flexible Ordering and Customization

Small-scale batches are available in various forms, such as standard bars (10–15 kg), rods, pellets, or granules—perfectly matching your exact production needs.

Superior Surface Quality

Carefully cleaned and chemically etched surfaces, vacuum-sealed or argon-filled packaging, ensuring optimal condition upon delivery.

Certified and Compliant

Every batch comes with a Certificate of Analysis (CoA), fully compliant with ISO 9001:2015, RoHS, ASTM standards, giving you confidence and reliability.

Affordable Excellence & Expert Support

Competitive prices without compromising quality, backed by dedicated professionals offering personalized assistance to fully meet your specific needs.

Fast and Dependable Delivery

Consistent availability and fast delivery schedules, ensuring your production timelines are always met. We deliver worldwide by express, air, or sea freight.

Unique Properties of Aluminum Ingot

Lightweight Strength

Aluminum has a high strength-to-weight ratio, making it ideal for applications where reducing weight is critical—such as aerospace, automotive, and transportation.

Excellent Corrosion Resistance

One of the most valuable features of aluminum is its natural oxide layer, which protects it from corrosion, even in harsh environments like marine and chemical processing industries.

Superior Thermal and Electrical Conductivity

Aluminum ingots are widely used in electrical and thermal applications due to their outstanding conductivity. They're perfect for manufacturing components such as heat sinks, cables, and transformers.

High Ductility and Workability

Aluminum can be easily melted, cast, and fabricated into various forms. This makes it highly adaptable for customized manufacturing processes, from extrusion to die casting.

Recyclability

Aluminum is 100% recyclable without loss of quality. This not only reduces production costs but also supports sustainability efforts across industries.

Aluminum Ingot Manufacturing Process

The production of aluminum ingots is a meticulous process that ensures high purity, consistent structure, and optimal performance for downstream applications. At AEM Deposition, we adhere to stringent manufacturing standards to produce top-grade aluminum ingots suitable for further transformation into billets or end-use components.

Step-by-Step Overview

-

Raw Material Sourcing

The process begins with either bauxite ore—the primary source of aluminum—or recycled aluminum materials, supporting a more sustainable production cycle. The bauxite is refined through the Bayer Process to extract alumina (Al₂O₃), which is then used for smelting. -

Electrolytic Smelting

Using the Hall-Héroult process, alumina is dissolved in molten cryolite and subjected to electrolysis. This separates pure aluminum metal from oxygen, resulting in molten aluminum ready for casting. -

Casting into Ingots

The molten aluminum is then cast into ingot molds through a direct chill casting process. This method involves cooling the metal rapidly with water during casting, which enhances the structural integrity and surface finish of the ingots. -

Cooling and Inspection

After casting, the ingots are cooled and undergo strict quality inspection to check for uniformity, surface defects, and chemical composition. This ensures each ingot meets industry standards and customer specifications.

Click to download datasheet about High Purity Aluminum Ingot

Click to download datasheet about High Purity Aluminum Ingot

Unable to find the required data sheet? Click here to send an email and get it.

Unable to find the required data sheet? Click here to send an email and get it.

Click here to get answers to Frequently Asked Questions (FAQ).

Click here to get answers to Frequently Asked Questions (FAQ).