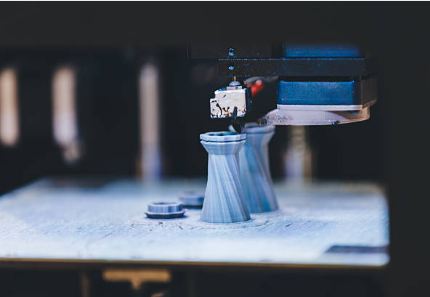

Additive Manufacturing (3D Printing)

Metal Powders for Additive Manufacturing 3D Printing

Metal powders for additive manufacturing (also known as 3D printing) are a type of material used in the process of creating physical objects by building them up layer by layer.

In additive manufacturing using metal powders, a metal powder is deposited in layers and then fused together using a high-energy source, such as a laser or an electron beam.

There are several types of metal powders that can be used in additive manufacturing, including stainless steel, titanium, aluminum, Co-based alloy, and Ni-based alloy. The choice of metal powder depends on the specific application and the desired properties of the final object.

One of the main advantages of using metal powders in additive manufacturing is that they allow for the creation of complex, customized parts and objects with precise control over their shape and size. This can be especially useful in the manufacturing of parts for the aerospace, automotive, and medical industries, where precision and customizability are often critical.

Types of 3D printing metal powder

There are several types of metal powders that can be used in 3D printing (also known as additive manufacturing), our company product mainly including:

Stainless steel:

Stainless steel is a strong and corrosion-resistant metal that is commonly used in 3D printing. It is suitable for a wide range of applications, including aerospace, automotive, and medical parts.

Cobalt based Alloy:

Cobalt is a strong and corrosion-resistant metal that is commonly used in 3D printing. It is often used in the production of medical and dental implants due to its biocompatibility and high strength.

Nickel-based Alloy:

Nickel is a strong and corrosion-resistant metal that is commonly used in 3D printing. It is often used in the production of aerospace and automotive parts due to its high strength and low density.

We provide additive manufacturing (3D printing) powder according to your customized requirements.

Characteristics of 3D Printing Metal Powder

There are several characteristics of metal powders that are used in 3D printing:

Particle size:

The size of the metal particles in the powder can have a significant impact on the properties of the final printed part. Smaller particle sizes can result in higher resolution and finer features, but may also result in longer print times and higher costs.

Flowability:

Metal powders used in 3D printing should have good flowability, meaning they can be easily poured and spread out into a thin layer. This is important for ensuring that the powder can be properly distributed in the printer bed.

Porosity:

Porosity, or the presence of small voids or pores in the printed part, can affect the mechanical and thermal properties of the part. Metal powders with low porosity tend to result in stronger and more durable parts.

Chemical purity:

The chemical purity of the metal powder can impact the quality and consistency of the printed parts. Impurities can result in defects or variations in the final part.

Cost:

The cost of metal powders can vary significantly depending on the type of metal, the particle size, and the supplier. It is important to consider the cost when selecting a metal powder for 3D printing.

Health and safety:

Some metal powders can be hazardous to handle, as they may produce dust or fumes that can be harmful to inhale. It is important to follow proper safety procedures when handling metal powders and to use appropriate personal protective equipment.

Specification

|

Particle Size |

Tapping Density(g/cm³) |

Flowability(s) |

ParticleSize Distribution (um) |

||

|---|---|---|---|---|---|

|

D10 |

D50 |

D90 |

|||

|

15-45um |

4.9-5.3 |

≤20s |

18-22 |

27-35 |

49-55 |

|

10-45um |

4.9-5.3 |

≤20s |

10-15 |

22-28 |

41-48 |

|

10-30um |

4.8-5.2 |

≤25s |

11-15 |

20-25 |

34-40 |

Note: Other specifications are available upon any customer requirements.

Additive Manufacturing 3D Printing Metal Powder Manufacturer

Welcome to AEM Deposition, a China manufacturer of high-quality additive manufacturing 3D printing powders. We are committed to providing our customers with the best possible materials for their 3D printing needs, and we pride ourselves on offering a wide range of benefits to our clients.

We offer a variety of powders in different sizes, shapes, and alloys, ensuring that our customers can find the perfect material for their specific application. Our powders are carefully processed and tested to ensure that they meet the highest standards of purity and performance.

Our team of experienced professionals is always available to provide support and guidance to our customers. Whether you have a specific project in mind or just need help choosing the right powder for your needs, we are here to help.

Choose AEM Deposition as your additive manufacturing 3D printing powder manufacturer and experience the difference for yourself.

Service every customer with care & professional.

Integrated Production Line

AEM is equipped with a complete set of production and processing facilities in particular high standard cleaning room .

Strict Quality Control - ISO9001

AEM runs a strict quality control system involving raw materials selection, production control, product inspection, fine packing.

Comprehensive Solutions - Timely service

we can help customers select materials, design products, and provide full technical and after-sales service support.

Applications of 3D Printing Powder

3D printing powder is used in a variety of applications, including:

Industrial manufacturing:

3D printing with metal powders is increasingly being used in industrial manufacturing to produce custom parts and components. This can include everything from automotive parts and aerospace components to medical devices and consumer products..

Prototyping:

3D printing with metal powders is a fast and cost-effective way to produce prototypes and proof-of-concept models. This allows designers and engineers to quickly iterate and test different designs before committing to full-scale production.

Tooling:

It can be used to produce custom tooling and fixtures for a variety of applications. This can include jigs, fixtures, and molds for injection molding, casting, and other manufacturing processes.

Art and sculpture:

The powders has also been used to create unique and complex art pieces and sculptures. The ability to create intricate, organic shapes and structures makes 3D printing with metal powders an attractive option for artists.

Medical and dental:

Metal powders are also used in 3D printing to produce custom medical and dental implants and prosthetics. 3D printing allows for the creation of customized, patient-specific implants that are tailored to fit perfectly and improve patient outcomes.