Tantalum Powder

Tantalum Powder

Tantalum is twice as dense as steel and it is highly ductile at high temperatures. It has the fourth highest melting point of all metals and is able to form extremely thin and protective oxide layers for high-quality capacitors. Our tantalum powder has high surface area and great handling and flow properties.Tantalum powder can be divided into three categories for capacitor tantalum, metallurgical tantalum and Voltage Tantalum Powder.

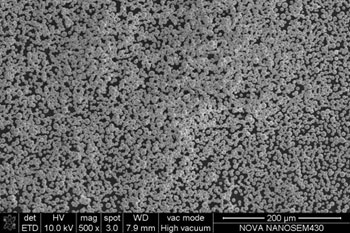

High-capacitance Tantalum Powder

Features:

• Produced by the sodium reduction method.

• It’s suitable for making capacitors with a rated withstand voltage of 4v-40v.

• Excellent materials for making chips, impregnated tantalum electrolytic capacitors and organic polymer polymer capacitors, which have the advantages of good moldability, high specific capacitance, small leakage current, and low equivalent series resistance.

Electrical Properties

| Grade |

Capacitance(+10%-6%) (μFV/g) |

Volume shrinkage (%) |

Current leakage (nA/μFV) |

Dissipation factor (%) |

Breakdown voltage (V) |

|---|---|---|---|---|---|

| FTa16-700 | 70000 | ≤15 | ≤0.5 | ≤40 | ≥120 |

| FTa16-500 | 50000 | ≤18 | ≤0.4 | ≤25 | ≥120 |

| FTa16-400 | 40000 | ≤18 | ≤0.4 | ≤20 | ≥120 |

| FTa16-300 | 30000 | ≤18 | ≤0.4 | ≤20 | ≥120 |

| FTa16-230 | 23000 | ≤18 | ≤0.4 | ≤15 | ≥140 |

Chemical Analysis of Tantalum Powder(Maximum Values/wt ppm)

| Grade | O | C | N | H | Fe | Ni | Cr | Si | Ti | Nb | Na+K | W | Mo |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| FTa16-700 | 4000 | 40 | 1000 | 180 | 30 | 30 | 20 | 20 | 5 | 30 | 40 | 10 | 5 |

| FTa16-500 | 3500 | 40 | 500 | 170 | 30 | 30 | 20 | 20 | 5 | 30 | 30 | 10 | 5 |

| FTa16-400 | 3000 | 40 | 500 | 170 | 30 | 30 | 20 | 20 | 5 | 30 | 30 | 10 | 5 |

| FTa16-300 | 2500 | 30 | 400 | 120 | 30 | 30 | 20 | 20 | 5 | 30 | 30 | 10 | 5 |

| FTa16-230 | 2500 | 30 | 150 | 120 | 30 | 30 | 20 | 20 | 5 | 30 | 20 | 10 | 5 |

Physical Properties

| Grade | Bulk density(g/cm3) | Average fisher size(um) |

Particle-size distribution (-325mesh%) |

|---|---|---|---|

| FTa16-700 | 1.5-2.1 | 1.8-3.0 | ≤35 |

| FTa16-500 | 1.6-2.2 | 2.0-3.4 | ≤35 |

| FTa16-400 | 1.6-2.2 | 2.0-3.5 | ≤35 |

| FTa16-300 | 1.7-2.3 | 2.4-3.5 | ≤35 |

| FTa16-230 | 1.7-2.3 | 2.4-3.5 | ≤35 |

Middle-Voltage Tantalum Powder

Features:

• Simple flake shape.

• Larger Fischer particle size and smaller specific surface area

• Good sintering resistance, high reliability and high voltage resistance

• It’s suitable for making medium to high voltage solid tantalum electrolytic capacitors with high reliability requirements from 20 to 63V.

Electrical Properties

| Grade |

Capacitance(+10%-6%) (u FV/g) |

Current leakage (nA/u FV) |

Dissipation factor (%) |

Breakdown voltage (V) |

|---|---|---|---|---|

| FDP-100 | 10000 | ≤0.4 | ≤10 | ≥180 |

| FDP -80 | 8000 | ≤0.4 | ≤10 | ≥230 |

| FDB -52 | 5200 | ≤0.5 | ≤8 | ≥240 |

| FTa40-42 | 4200 | ≤0.5 | ≤8 | ≥240 |

Chemical Analysis (Maximum Values/wt ppm)

| Grade | O | C | N | Fe | Ni | Cr | Si | Ti | Nb | Na | K | W | Mo | Al | Mn |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| FDP-100 | 2200 | 60 | 100 | 50 | 10 | 15 | 20 | 5 | 30 | 15 | 15 | 20 | 10 | 5 | 5 |

| FDP-80 | 2100 | 60 | 100 | 50 | 10 | 15 | 20 | 5 | 30 | 10 | 10 | 20 | 10 | 5 | 5 |

| FDB-52 | 1700 | 45 | 50 | 35 | 10 | 15 | 20 | 5 | 30 | 10 | 10 | 20 | 10 | 5 | 5 |

| FTa40-42 | 1700 | 45 | 50 | 35 | 10 | 15 | 20 | 5 | 30 | 10 | 10 | 20 | 10 | 5 | 5 |

Physical Properties

|

Grade |

Bulk density (g/cm3) |

Average fisher size (um) |

Particle-size distribution |

|---|---|---|---|

|

FDP-100 |

1.5-2.3 |

3.0-5.0 |

≤30 |

|

FDP-80 |

1.7-2.5 |

3.0-5.0 |

≤30 |

|

FDB-52 |

3.0-4.0 |

4.5-8.0 |

≤30 |

|

FTa40-42 |

3.5-4.5 |

5.0-9.0 |

≤30 |

High-Voltage Tantalum Powder

Features:

• Simple structure.

• Smaller specific surface area

• Good voltage resistance, and high breakdown voltage

• It’s suitable for making medium to high voltage solid tantalum electrolytic capacitors with specifications greater than 63V

Electrical Properties

|

Grade |

Capacitance |

Current leakage |

Dissipation factor |

Breakdown voltage |

|---|---|---|---|---|

|

FTa50-50 |

5000 |

≤0.6 |

≤6 |

≥260 |

|

FTa50-40 |

4000 |

≤0.6 |

≤6 |

≥260 |

|

FDC-50 |

5000 |

≤0.7 |

≤6 |

≥300 |

|

FTa63-40 |

4000 |

≤0.7 |

≤6 |

≥300 |

|

FTa63-35 |

3500 |

≤0.7 |

≤6 |

≥300 |

|

FTa63-28 |

2800 |

≤0.7 |

≤5 |

≥300 |

|

FTa63-25 |

2500 |

≤0.7 |

≤4 |

≥300 |

|

FTa63-20 |

2000 |

≤0.7 |

≤3 |

≥300 |

|

FTa63-15 |

1500 |

≤0.7 |

≤3 |

≥300 |

|

FTa63-10 |

1000 |

≤0.7 |

≤3 |

≥300 |

Chemical Analysis (Maximum Values/wt ppm)

|

Grade |

O |

N |

C |

Fe |

Ni |

Cr |

Si |

Ti |

Nb |

W |

Mo |

AL |

Mn |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

FTa50-50 |

1800 |

60 |

50 |

40 |

15 |

15 |

20 |

10 |

30 |

10 |

10 |

5 |

5 |

|

FTa50-40 |

1600 |

60 |

50 |

40 |

15 |

15 |

20 |

10 |

30 |

10 |

10 |

5 |

5 |

|

FDC-50 |

2000 |

60 |

60 |

50 |

15 |

15 |

20 |

10 |

30 |

10 |

10 |

5 |

5 |

|

FTa63-40 |

1800 |

60 |

40 |

35 |

15 |

15 |

20 |

10 |

30 |

10 |

10 |

5 |

5 |

|

FTa63-35 |

1600 |

60 |

40 |

30 |

15 |

15 |

20 |

10 |

30 |

10 |

10 |

5 |

5 |

|

FTa63-28 |

1400 |

40 |

30 |

20 |

10 |

10 |

20 |

10 |

30 |

10 |

10 |

5 |

5 |

|

FTa63-25 |

1400 |

40 |

30 |

20 |

10 |

10 |

20 |

10 |

30 |

10 |

10 |

5 |

5 |

|

FTa63-20 |

1200 |

40 |

25 |

15 |

10 |

10 |

20 |

5 |

30 |

10 |

10 |

5 |

5 |

|

FTa63-15 |

1000 |

40 |

25 |

15 |

10 |

10 |

20 |

5 |

30 |

10 |

10 |

5 |

5 |

|

FTa63-10 |

1000 |

40 |

25 |

15 |

10 |

10 |

20 |

5 |

30 |

10 |

10 |

5 |

5 |

Physical Properties

|

Grade |

Bulk density(g/cm3) |

Average fisher size(μm) |

|---|---|---|

|

FTa50-50 |

2.5-3.5 |

5.5-7.5 |

|

FTa50-40 |

3.0-4.0 |

7.5-11.0 |

|

FDC-50 |

2.5-3.5 |

4.0-7.0 |

|

FTa63-40 |

3.5-4.5 |

8.0-11.0 |

|

FTa63-35 |

3.5-4.5 |

8.0-12.0 |

|

FTa63-28 |

3.5-5.5 |

8.0-12.0 |

|

FTa63-25 |

4.0-6.0 |

9.0-14.0 |

|

FTa63-20 |

4.0-6.0 |

8.0-13.0 |

|

FTa63-15 |

5.0-6.5 |

9.0-15.0 |

|

FTa63-10 |

5.5-6.5 |

10.0-20.0 |

Tantalum powder for metallurgical purposes

Features:

• Appearance: Dark grey powder or black powder.

• Application: Used for making various tantalum processing materials and alloy additives

Grade:FTa-01, FTa-02, FTa-1

|

Grade |

FTa-01 |

FTa-02 |

FTa-1 |

|

|---|---|---|---|---|

|

Main content |

Ta,%,Minimum |

99.95 |

99.95 |

99.95 |

|

Impurity content , |

O |

0.100 |

0.120 |

0.180 |

|

C |

0.005 |

0.005 |

0.008 |

|

|

N |

0.005 |

0.005 |

0.008 |

|

|

H |

0.003 |

0.003 |

0.003 |

|

|

Fe |

0.004 |

0.004 |

0.005 |

|

|

Ni |

0.003 |

0.003 |

0.005 |

|

|

Cr |

0.003 |

0.003 |

0.005 |

|

|

Nb |

0.003 |

0.003 |

0.005 |

|

|

W |

0.002 |

0.002 |

0.002 |

|

|

Mo |

0.001 |

0.001 |

0.002 |

|

|

Si |

0.003 |

0.003 |

0.005 |

|

|

Mn |

0.001 |

0.001 |

0.001 |

|

|

Ti |

0.001 |

0.001 |

0.001 |

|

|

Fsss(um) |

3.0-10.0 |

3.0-10.0 |

3.0-10.0 |

|

|

Sieve mesh |

-80 |

-80 |

-80 |

|

|

Application |

Tantalum processing and alloying additives |

|||

|

Special requirements to be agreed upon by the supplier and buyer |

||||

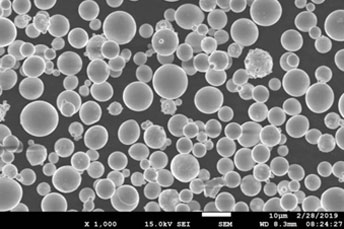

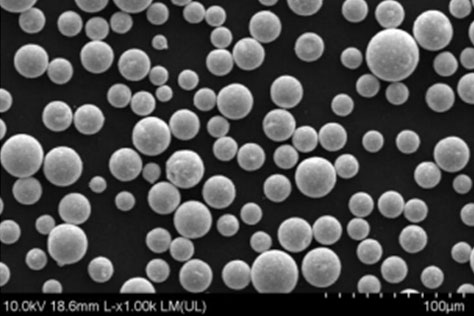

Spherical Tantalum Powder

Physical Properties

| Size | 15-53 um | ||||

| Apparet density | 9.75 g/cm3 | ||||

| Tap density | 10.8 g/cm3 | ||||

| Hall flow rate | 5.8 s/50g |

Chemical Composition

| Chemical Composition - by ICP-AES | ||||||||

| Element | Ta | Fe | Mg | Cu | Al | Ca | Sn | Mn |

| Value (%) | ≥99.9 | 0.002 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 |

| Element | Ti | Mo | W | Nb | Si | Cr | Ni | |

| Value (%) | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | |

| Gas Impurities | ||||||||

| Element | C | H | O | N | ||||

| Value (%) | 0.002 | 0.0018 | 0.045 | 0.004 | ||||

Tantalum Powder Features

- High resistance to corrosion;

- Resistant to high temperature.

Tantalum Powder Application

- Additive manufacturing (AM);

- Thermal spray (TSA);

Packing of Tantalum Powder:

Related Powders of Tantalum Powder

| Tantalum Powder | |||

| More Powder |

Related Products of Tantalum Powder

|

N/A

|

Ceramic Sputtering Targets Tantalum Carbide Sputtering Target |

|

|

Evaporation Materials Tantalum Evaporation Pellet |

Crucibles Tantalum Crucible |

Metal Powders Tantalum Powder |

Click to download datasheet about Tantalum Powder

Click to download datasheet about Tantalum Powder

Unable to find the required data sheet? Click here to send an email and get it.

Unable to find the required data sheet? Click here to send an email and get it.

Click here to get answers to Frequently Asked Questions (FAQ).

Click here to get answers to Frequently Asked Questions (FAQ).