+86-731-89578196

+86-731-89578196

[email protected]

[email protected]

- Home

- Our Company

-

Products

Sputtering Targets

- Industries

- Blog

- FAQ

- Contact Us

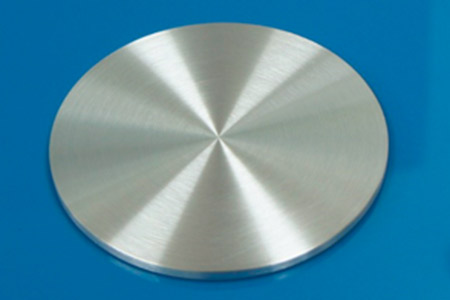

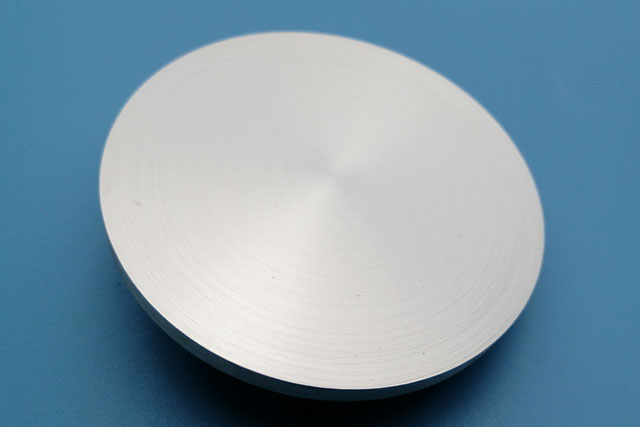

High Purity Precious Metal Sputtering Targets

Precious Metals, such as Gold, Silver, and Platinum, are used in semiconductors and microelectronics. Precious Metals thin-film players can serve as a barrier against oxidation for retaining good electrical connectivity, as the medium for soldering, as an electrical contact layer, an alloy constituent for semiconductor effects, such as in Schottky or Zener Diodes, connecting layers, as a base for wire bonding, and other applications.

AEM Deposition, a globally active business, is one of the leading producers of coating materials for physical vapor deposition (PVD) with more than 10 years of experience in this field. Our semiconductor portfolio covers a wide range of highly effective sputtering targets and evaporation materials. Meanwhile, AEM Deposition also provides target bonding service, evaporation source (crucible, evaporation boats, thermal filaments), and substrates & wafers. Good international reputation is the assurance of quality.

Types of Precious Metal Sputtering Targets from AEM Deposition:

Gold Sputtering Targets (Au), purity: 99.99-99.999%

Sliver Sputtering Targets (Ag), purity: 99.99%

Iridium Sputtering Targets (Ir), purity: 99.9%

Palladium Sputtering Targets (Pd), purity: 99.95%

Platinum Sputtering Targets (Pt), purity: 99.99%

Rhodium Sputtering Targets (Rh), purity: 99.95%

Ruthenium Sputtering Targets (Ru), purity: 99.9%

Copper Silver Sputtering Targets (Cu/Ag), purity: 99.9%

Gold Copper Sputtering Targets (Au/Cu), purity: 99.9%

Gold Palladium Sputtering Targets (Au/Pd), purity: 99.9%

Gold Tin Sputtering Targets (Au/Sn), purity: 99.9%

Silver Palladium Sputtering Targets (Ag/Pd), purity: 99.9%

Iridium Manganese Sputtering Targets (Ir/Mn), purity: 99.9%

Circular: Diameter <= 14inch, Thickness >= 1mm;

Block: Length <= 32 inch, Width <= 12 inch, Thickness >= 1 mm.

Production Process of Precious Metal Targets

Most of the precious metals can be processed by melting, casting, and subsequent thermo-mechanical transformation. For some precious metal alloys and selected precious metals, such as Iridium, powder processing is the established processing route. AEM Deposition provides products manufactured with state of the art processes best suited for each precious metal or precious metal alloy.

Analysis

Density of Precious Metal Sputtering Targets

In all products obtained by melting and casting, full density (100% of theoretical) is obtained. Products manufactured by the powder metal-liturgical process are provided with the highest possible density available according to best know practice.

Target Bonding Service

AEM Deposition thin-film products use its proprietary target bonding method, based on a flux-free solder technique. Thin-film adhesion and diffusion barrier layers are applied to the back of each precious metal sputtering targets, followed by a temperature-controlled metallic solder seal between the precious metal target and backing plate. The bonding is compliant to accommodate mechanical and thermal stress.

Packaging of Precious Metal Targets

Final cleaning and packaging are completed under clean-room conditions. All precious metal targets are vacuum-sealed in argon-filled polyethylene bags, guaranteeing consistent sputtering target performance, even when stored for a longer period.