+86-731-89578196

+86-731-89578196

[email protected]

[email protected]

- Home

- Our Company

-

Products

Sputtering Targets

- Industries

- Blog

- FAQ

- Contact Us

Comprehensive Guide to Transparent Conducting Oxides (TCOs)

1. Introduction

Have you ever wondered how the touchscreens on your smartphone or the energy-efficient windows in your office building work so seamlessly? Behind these innovations lies a material known as transparent conducting oxide (TCO).

So, what exactly are TCOs? Simply put, they’re materials that combine two essential properties:

- Transparency – allowing light to pass through,

- Electrical conductivity – enabling them to carry electricity.

This unique combination makes TCOs essential in a wide range of applications, from smartphone displays and solar panels to energy-efficient windows and advanced sensors. These technologies are a part of our daily lives, yet the science behind them often goes unnoticed.

At AEM Deposition, we play a critical role in the creation of TCO films. We supply sputtering targets, which are used to deposit high-quality, thin layers of transparent conducting oxides onto various substrates. Our sputtering targets are designed to ensure that TCO films are not only durable and reliable but also deliver the performance that modern technologies demand.

In this blog, we’ll explore what TCOs are, why they’re so important, and how AEM Deposition’s sputtering targets help manufacturers create these essential materials.

2. What Are Transparent Conducting Oxides (TCOs)?

Transparent conducting oxides, or TCOs, are a unique class of materials that are both transparent to visible light and capable of conducting electricity. This combination of properties makes them indispensable in a wide variety of modern technologies.

Key Properties of TCOs

-

Transparency:

TCOs allow visible light to pass through with minimal absorption. This transparency is essential in applications like displays, where a clear and sharp image is required, and energy-efficient windows, where you want natural light but not excessive heat. -

Electrical Conductivity:

While being transparent, TCOs also need to conduct electricity efficiently. This is vital for touchscreens, solar panels, and even smart windows, where the ability to carry current while maintaining clarity is crucial. -

Durability:

TCOs are not only transparent and conductive, but they also need to be stable over time, resisting degradation from environmental factors like UV light, moisture, or temperature changes. This durability ensures that the devices using TCOs—like your phone screen or solar panel—continue to perform effectively for years.

Common TCO Materials

There are several types of TCOs, but some of the most commonly used include:

-

Indium Tin Oxide (ITO):

ITO is one of the most well-known and widely used TCO materials, especially in touchscreens and flat-panel displays. Its high transparency and good conductivity make it ideal for these applications. However, its limited availability and cost are pushing manufacturers to explore alternatives.

-

Fluorine-Doped Tin Oxide (FTO):

FTO is often used in solar cells and energy-efficient windows. It’s a great choice for applications where durability and resistance to high temperatures are needed. FTO is also more cost-effective compared to ITO, making it an attractive option for some industries.

-

Aluminum-Doped Zinc Oxide (AZO):

AZO is another alternative to ITO, offering good transparency and conductivity at a more affordable price. It is commonly used in solar cells and transparent electronics and is an excellent choice for large-scale production.

Each TCO material has its own set of advantages, depending on the specific application, cost considerations, and performance requirements. At AEM Deposition, we understand the nuances of each material and offer customized sputtering targets to help manufacturers achieve the best possible TCO films for their needs.

Common Uses of Transparent Conducting Oxides (TCOs)

Transparent conducting oxides (TCOs) are special materials that combine transparency with electrical conductivity. This makes them important in many modern technologies. Here are some of the main areas where TCOs are used:

1. Touchscreen Displays and Electronics

TCOs are essential for touchscreen technology. Devices like phones, tablets, and laptops use a thin layer of Indium Tin Oxide (ITO) to make the screen responsive to touch.

TCOs create transparent electrodes that detect touch and turn it into electrical signals. These electrodes need to be both conductive and see-through to give users a smooth, clear experience. TCOs are also found in OLED screens, LCD panels, and touch-sensitive surfaces in devices like kiosks and car displays.

2. Solar Energy (Solar Panels)

TCOs are important in solar panels, which turn sunlight into electricity. The top layer of solar cells needs to let light pass through while carrying away the electricity generated.

Fluorine-Doped Tin Oxide (FTO) is often used in thin-film solar cells, while ITO is used in traditional silicon solar panels. As demand for renewable energy grows, TCOs help make solar power more efficient and affordable.

3. Energy-Efficient Smart Windows

TCOs are also used in smart windows, which can change their transparency based on heat or light. These windows help save energy by reducing the need for lights or air conditioning.

TCOs like FTO and ITO allow smart windows to stay transparent while adjusting their properties. Electrochromic windows, which change color or opacity with electricity, rely on TCOs. As green building technology grows, the need for energy-efficient windows—and the role of TCOs—will keep increasing.

4. Sensors and Flexible Displays

TCOs are used in various sensors, like gas, biosensors, and pressure sensors, where transparency and conductivity are key. These sensors detect changes in electrical signals while staying unobtrusive in medical devices and smart clothing.

TCOs are also found in flexible displays and smart textiles, where they need to bend or stretch without losing conductivity. As more devices become flexible or wearable, TCOs will continue to play an important role.

TCOs in a Changing World

These examples show how TCOs are used in different industries today. As demand for better electronics, clean energy, and smart technologies increases, TCOs will become even more important.

At AEM Deposition, we provide high-quality sputtering targets to help create the next generation of TCO materials. Whether for displays, solar energy, or smart technologies, our customized sputtering targets ensure your TCO films meet the highest standards for performance and reliability.

4. The Role of Sputtering Targets in Making High-Quality TCO Films

To create the best transparent conducting oxide (TCO) films, you need the right materials, and that’s where sputtering targets come in. These targets are essential in producing thin films of TCOs with the exact properties required for various technologies.

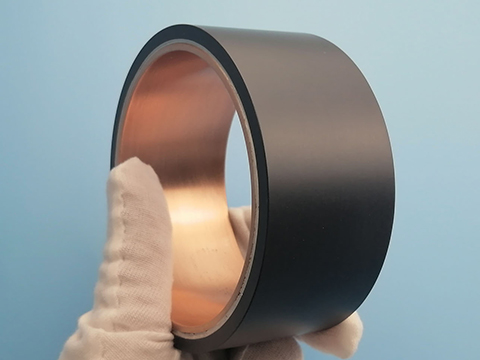

What Are Sputtering Targets?

A sputtering target is a material, often made of metal or ceramic, used in a process called sputtering. In sputtering, particles are shot at the target, causing atoms to be ejected and deposited onto a surface, creating a thin film. For TCO films, sputtering targets are made from materials that combine transparency and conductivity, like Indium Tin Oxide (ITO) Sputtering Target or Aluminum-doped Zinc Oxide (AZO) Sputtering Target.

Why High-Quality Sputtering Targets Matter

The quality of the sputtering target has a direct impact on the performance of the TCO films. Here's why:

-

Consistency

High-quality targets ensure that the TCO film is applied evenly, which is crucial for uniform conductivity and transparency. This consistency is especially important in devices like touchscreens or solar panels, where small variations can affect performance. -

Purity

Pure materials lead to higher-quality films. Impurities in the target material can cause defects in the film, affecting electrical conductivity or transparency. At AEM Deposition, we provide high-purity sputtering targets to ensure the best results. -

Durability

Sputtering targets need to withstand high-energy conditions during the sputtering process. Our durable targets ensure that the deposition process is smooth, which results in better performance and more consistent production. -

Customization

Every TCO application is different. Whether you're making smart windows, displays, or solar cells, the target material needs to be customized. AEM Deposition works with clients to create sputtering targets tailored to their specific needs.

How the Sputtering Process Works

Here’s a quick look at how sputtering creates high-quality TCO films:

- Prepare the Target: The target, made of a material like ITO or FTO, is ready to be used in the sputtering process.

- Sputtering: The target is placed in a vacuum chamber, and argon gas is used to hit the target. This knocks atoms off the target, which are then deposited onto a surface to form the thin TCO film.

- Film Formation: The atoms form a thin, even layer on the surface, creating a TCO film. The thickness of the film is carefully controlled during this process.

- Finishing Touches: After deposition, the film may be heated (annealed) to improve its properties like conductivity.

8. Conclusion

Transparent Conducting Oxides (TCOs) are a key part of many technologies that make our lives easier and smarter—think smartphones, solar panels, and touchscreens. They’re the perfect combination of transparency and conductivity, making them essential for everything from clean energy to advanced electronics.

At AEM Deposition, we provide the high-quality sputtering targets that are crucial for creating the best TCO films. We know that to make TCO films perform their best, every layer needs to be consistent, pure, and durable. That’s why we offer custom sputtering targets that fit your exact needs, ensuring your projects get the best results possible.

As the world shifts toward smarter, greener technologies, TCOs will continue to play an important role. By partnering with AEM Deposition, you’re working with a team that’s committed to helping you achieve the best performance, no matter what your project is.

If you’re ready to take your TCO applications to the next level, let’s talk. We’re here to help you get the right sputtering targets, every time, and bring your vision to life.