Silicon Carbide Sputtering Targets (SiC)

| Material Type | Silicon Carbide |

| Symbol | SiC |

| Melting Point (°C) | ~2,700 |

| Theoretical Density (g/cc) | 3.22 |

| Z Ratio | **1.00 |

| Sputter | RF |

|

Max Power Density* (Watts/Square Inch) |

30 |

| Type of Bond | Indium, Elastomer |

| Comments | Sputtering preferred. |

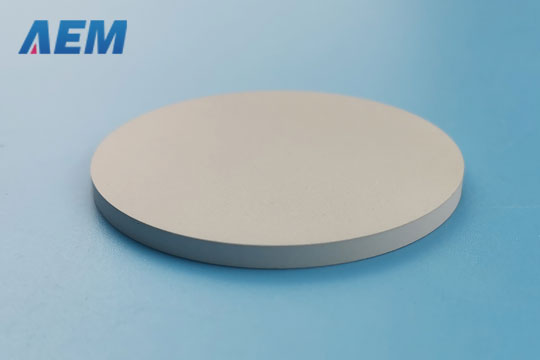

Silicon Carbide Sputtering Targets

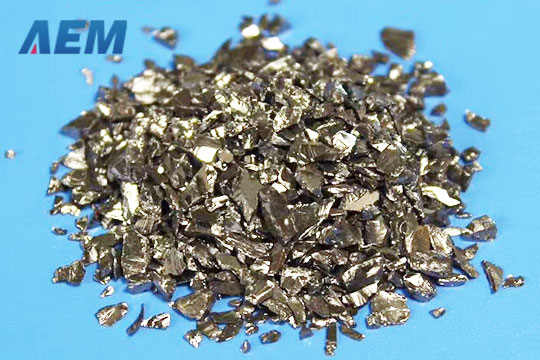

Silicon carbide (SiC), also known as carborundum, is a silicon and carbon compound with the chemical formula SiC. It occurs in nature as the extremely rare mineral moissanite. Synthetic silicon carbide powder has been mass-produced since 1893 for use as an abrasive. Grains of silicon carbide can be bonded together by sintering to form tough ceramics widely used in applications requiring high endurance, such as car brakes, car clutches, and ceramic plates in bulletproof vests. Electronic silicon carbide applications such as light-emitting diodes (LEDs) and detectors in early radios were first demonstrated around 1907. SiC is used in semiconductor electronics devices that operate at high temperatures or high voltages, or both. Large single crystals of silicon carbide can be grown by the Lely method. They can be cut into gems known as synthetic moissanite. Silicon carbide with a high surface area can be produced from SiO2 contained in plant material.

Silicon Carbide Sputtering Targets Information

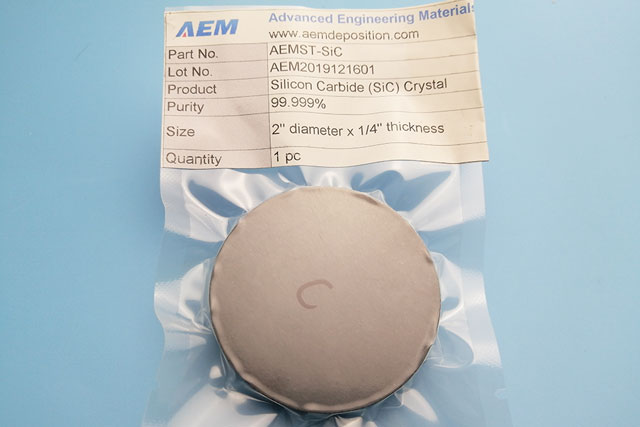

Silicon Carbide Sputtering Targets

Purity: 99.5%;

Circular: Diameter <= 14 inch, Thickness >= 1mm;

Block: Length <= 32 inch, Width <= 12 inch, Thickness >= 1mm.

Bonding is recommended for these materials. Many materials have characteristics that are not amenable to sputtering, such as brittleness and low thermal conductivity. This material may require a special ramp up and ramp down procedures. This process may not be necessary for other materials. Targets that have low thermal conductivity are susceptible to thermal shock.

More Information on Silicon Carbide Sputtering Targets

Applications

• Chemical Vapor Deposition (CVD) • Optical |

Features• High purity• Custom sizes available |

Manufacturing Process• Manufacturing - Hot pressed - Sintered, Elastomer bonded to backing plate

• Cleaning and final packaging, Cleaned for use in vacuum, |

Options

• 99.5% minimum purity

• Smaller sizes also available for R&D applications

• Sputtering target bonding service

|

Related Products of Silicon Carbon Sputtering Targets

|

N/A

|

Ceramic Sputtering Targets |

|

|

Evaporation Materials Silicon Evaporation Pellet |

Crucibles Graphite Crucible Quartz Crucible |

Metal Powders N/A |

Click to download datasheet about Silicon Carbide Sputtering Targets (SiC)

Click to download datasheet about Silicon Carbide Sputtering Targets (SiC)

Unable to find the required data sheet? Click here to send an email and get it.

Unable to find the required data sheet? Click here to send an email and get it.

Click here to get answers to Frequently Asked Questions (FAQ).

Click here to get answers to Frequently Asked Questions (FAQ).